Forage harvester GOMSELMASH FS80 PRO – high quality of chopping in the most difficult conditions and efficient work with medium and large volumes of forage harvesting.

Mowing tall-stalked crops, including corn in any phase of grain ripeness, picking dried seeded and natural grasses from swaths with simultaneous chopping and loading into vehicles – all this is within the power of the FS80 PRO harvester.

Comfortable workplace

The new spacious cab, developed on the basis of the LUX CAB, has a great panoramic view of the working area when using any adapters. The air suspension seat improves productivity and reduces operator fatigue. Multiple seat adjustments, a new steering column and steering wheel allow you to set up a comfortable working position and achieve maximum results throughout the work shift. In addition, thanks to the complex of vibration and noise insulation works, the harvesting process has become even quieter and more comfortable for the operator. Thanks to the logical arrangement of all instruments and elements in the cab, operating the combine becomes a simple and intuitive process.

The information system of the on-board computer HARVEST OFFICE makes the work of the combine operator as efficient and comfortable as possible. The HARVEST OFFICE system helps to manage and monitor in real time the state of the main functional units of the combine, control the working parts, engine, transmission, the progress of work and service operations, and also informs about the presence of warning and emergency situations.

The powerful lighting system of working area LED VISION provides an excellent visibility when working at night. Also, the location of the side mirrors has changed, which made it possible to reduce vibrations and improve visibility.

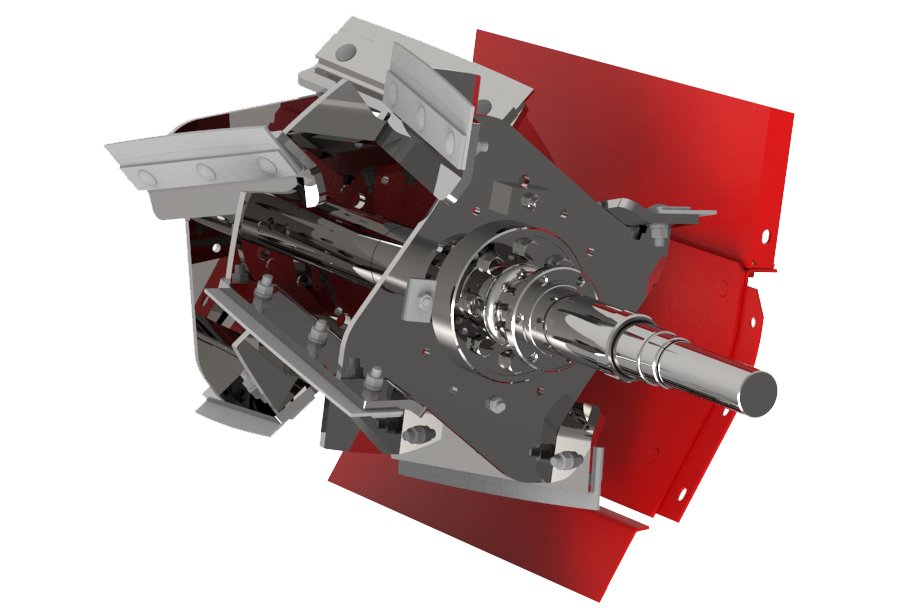

Using the AUTOSHARP system, it is possible to carry out automatic sharpening of the chopping drum knives from the combine cab. AUTOSHARP improves forage chopping quality and combine performance, while significantly reducing fuel consumption, and save your time and money. The number of sharpening cycles is set from the control panel in the cab.

In addition, the AUTOGAP automatic shearbar advance system is controlled directly from the cab, which greatly simplifies the operator's work and makes it easier to maintain high quality of cutting.

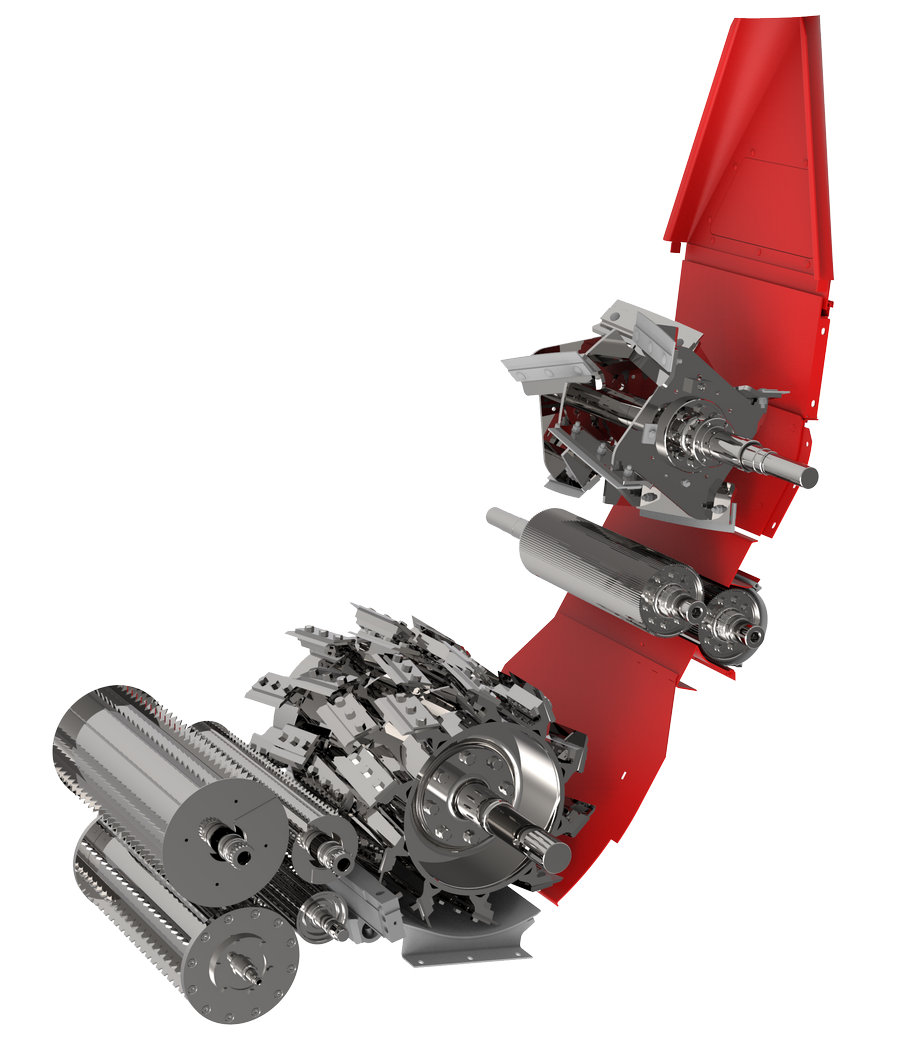

Time-tested feeder unit!

The front rollers of the feeder unit, made of high-quality non-magnetic stainless steel, have proven themselves in the most difficult harvesting conditions.

The lower feeder rollers are driven by a powerful hydraulic motor through a transmission. Thanks to this drive scheme, you get a reliable and steady start of the crop mass.

Many of the solutions in FS80 PRO are focused on being able to operate with minimum downtime and maximize your benefit. This also applies to the DRUM PROTECT system. The metal detector and stone detector sensors, installed in the front lower roller, send signals to the electronic unit of the control panel located in the cab. The system will instantly stop the drive of the feeder rollers, protecting the feeder and also saving you valuable time.

And with the help of the electrohydraulic reverse mechanism, the foreign object will be quickly removed by the reverse rotation of the rollers.

All ingenious – FS80 PRO

A direct-flow mass feed scheme is the shortest path from the feeder rolls to the exit from the silage spout with an increasing flow rate. This scheme determines the high throughput with minimal fuel consumption.

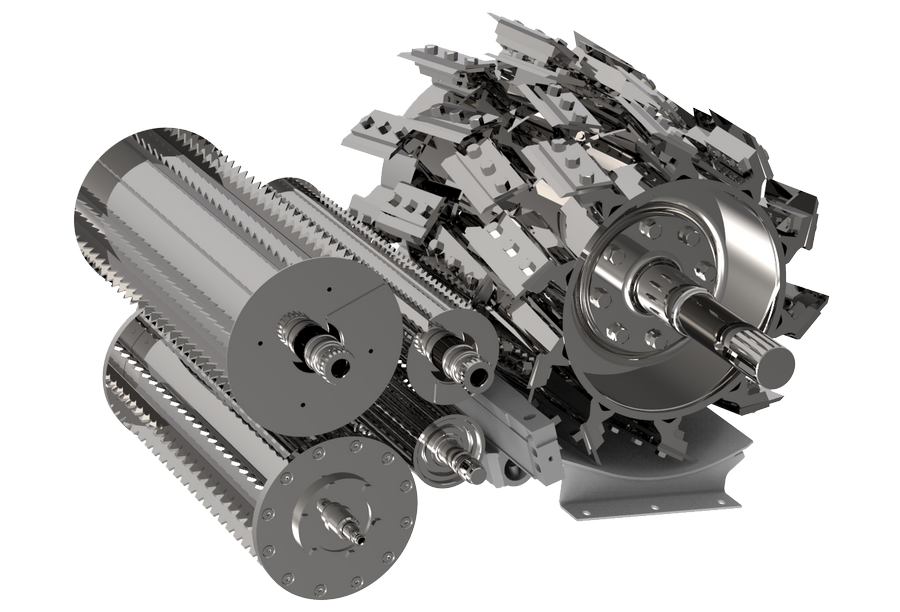

The MULTI DRUM universal chopping drum with 4 rows of knives is specially designed for efficient and economical cutting. Due to the special angle of the knives in relation to the shear bar, an oblique and clean cut is ensured with a reduction of cutting energy costs. The knives, due to the angle of inclination, shift the mass from the edges to the center of the drum, reducing the friction of the mass against the walls of the technological path, thereby reducing wear and increasing the efficiency of the technological process.

The drum width of 780 mm allows you to work without any issues and with full efficiency at a speed of 12 km/h.

The chopping drum DIRECT DRIVE system is carried out directly from the engine crankshaft. Such a scheme guarantees the highest efficiency of the power transmission and allows you to reduce the specific energy consumption.

Smooth adjustment of the cutting length is simply and conveniently made from the cab by turning the knob on the control panel in two ranges: 6-9 and 13-20 mm. For coarser chopping, it is possible to work with 20 knives on the drum and a cutting length of 12-18 and 26-40 mm.

To increase the operating life and reduce downtime for the repair of the chopping unit, special replaceable sheets of the chopping drum and the feed chamber are made of high wear-resistant material QUARD 500.

Corn crackers for all types of forage harvesting

Methods for harvesting maize silage currently differ significantly depending on the region and agricultural organization. “Gomselmash” responds flexibly to new trends in forage harvesting. Based on your wishes, three types of сorn crackers have been developed for the FS80 PRO harvester, the choice of which will help you get the best result.

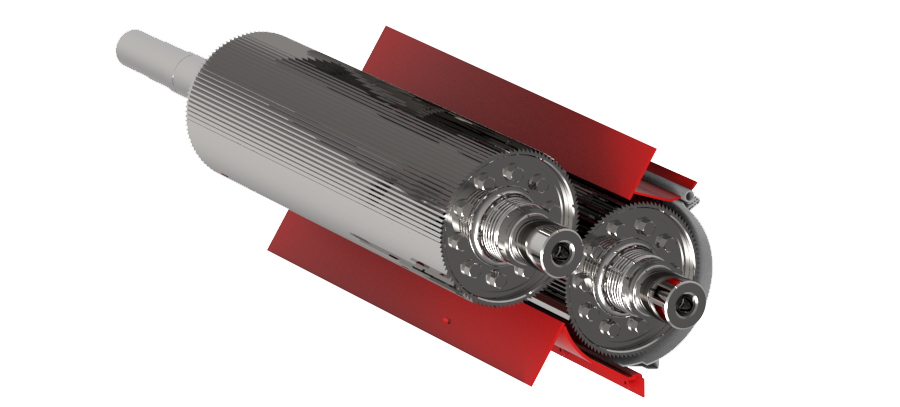

The OPTI ROLL CRACKER with serrated rollers and an optimal diameter of 196 mm allows for efficient corn crushing and cobs splitting, both for fine and coarse cutting.

The MAX DISC CRACKER with a larger diameter of 200 mm and fluted discs allows you to significantly increase the working area, which makes it possible to effectively crush corn with larger cuts. Also, due to the increased working area of the сorn cracker, its productivity is increased without loss of crushing efficiency.

The new SHARKLAGE CRACKER with serrated rollers and helical groove improves the efficiency of corn crushing even at cutting lengths of around 30 mm. Thanks to the increased difference in the rotation of the rollers of the SHARKLAGE CRACKER, in addition to perfect grain crushing, you get an excellent effect of grinding the feed mass, which increases the area of the crushed material. This effect is also achieved thanks to the helical groove, which simultaneously gives the effect of longitudinal and cross-sectional rubbing.

As a result, you get a high-quality feed mass with high digestibility rate and, as a result, an increase in the milk and meat productivity of your animals.

Direct mass loading

The accelerator allows you to maintain a high rate of work. The powerful flow of the chopped mass fills the bodies of vehicles extremely tightly, ensuring maximum use of their volume and reducing the number of transportations.

The 210° swivel angle of silage spout avoids difficult maneuvering. The design of the silage spout is developed in such a way that the flow of the feed mass is directed along the optimal arc and the minimum amount of energy is consumed for its transportation. To increase the operating life of the silage spout in places of greatest load, new easily removable plates made of wear-resistant steel of increased thickness have been implemented in the harvester. Such solutions are aimed at the possibility of maximizing the efficiency of the harvester with minimal downtime during the most difficult periods of harvesting forage crops.

Additional features and useful options

Increasing the preservation of feed and nutrients in them is guaranteed by the dosing system of silage additive, which is included in the standard configuration of the FS80 PRO harvester. Silage additives are injected into the chopped mass from an additional tank with a volume of 300 litres by pneumatic spraying, while the control over the consumption of additives is carried out automatically.

The ALS-SYSTEM installed on the FS80 PRO harvester gives you the possibility to make efficient use of working time, reducing downtime and maintenance time.

Optionally you have the opportunity to equip the harvester with the HARVEST HUB system for remote monitoring of parameters and operating modes. The system allows you to save data on the server, which optimizes the operation of the machine for you.

Harvesting of all types of forage crops

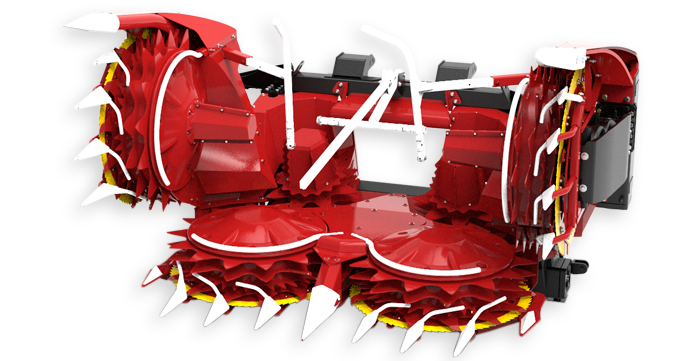

The adapters for the FS80 PRO harvester create the necessary conditions for high productivity and high-quality chopping: the rotary front attachments carry the corn stalks exactly in the direction of the long axis of the feeder unit, and the pick-ups, thanks to their design, provide the shortest path of the picked up mass to the rollers.

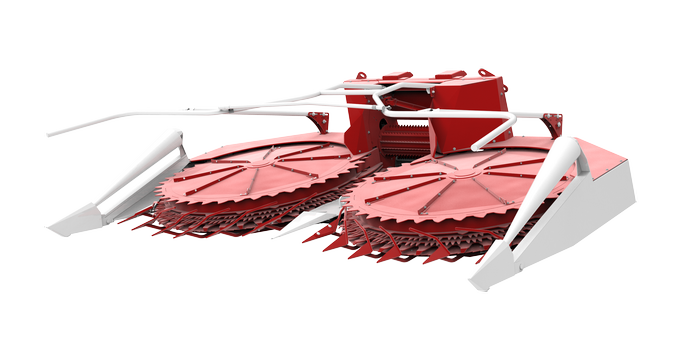

The rotary maize front attachment cuts the stalks cleanly and at the same height. The stalks are conveyed to the feeder unit only by the lower part. This allows you to completely avoid the loss of maize cobs, leaving a perfectly harvested field behind the machine. When harvesting wax ripeness corn with hard stalks and cobs, the quality of the cut and the uniformity of feeding of the cutting mass are still stable. To improve the convenience of transporting the harvester and save your time, “Gomselmash” has developed a new folding maize header.

When the FS80 PRO is used with a pick-up with feeler wheels, the contours of the field are copied accurately and without damage of the plant root system. The design of the pick-up provides the shortest path of the crop to the feeder unit, increasing the stability of the process. The pick-up device is located compactly under the auger, so when the feeder rolls are reversed, the crop is removed directly to the field. This does not require additional cleaning. In addition, you can improve harvester reliability with the new camless pick-up.

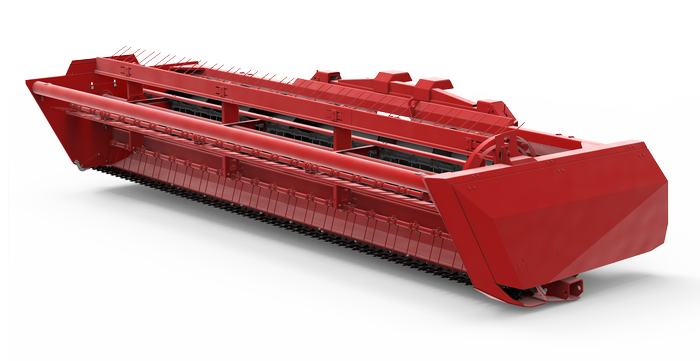

The use of grass headers on the FS80 PRO harvester with a ground-contour following system and cutting height adjustment guarantees an equally clean cut. The overrunning clutch of the reel drive pulley prevents damage to the reel during the reverse rotation of the screw.

You can get more detailed information about prices, terms of purchase and deliveries of harvesters from a dealer in your region.