The GOMSELMASH FS650 forage harvester provides forage harvesting in a short time, ideal chopping quality at a high feed speed. This is a high level of automated control of cleaning parameters, the most comfortable working conditions for the operator and convenience of service.

The FS650 harvester demonstrates high quality chopping in the most difficult conditions when working with large volumes of forage!

Comfort for high productivity

The new modern UNI CAB is equipped with everything necessary for comfortable operation of the harvester operator, and the bonus is excellent visibility from the workplace when working with any of the adapters.

An ergonomic joystick, video surveillance of work areas, an audio system, a refrigerator with heating function, climate control, USB connectors for connecting external devices, a 12V socket, organizers for storing documents and small items, an air-suspended chair with adjustments allow to configure individually and comfortably your workplace.

Thanks to the logical arrangement of all instruments and elements in the cab, operating the harvester becomes a simple and intuitive process.

The HARVEST OFFICE information and control system with a wide range of functions for automatic control, diagnostics, registration, warning and notification about abnormal operating conditions makes the work of the operator as efficient and comfortable as possible.

The HARVEST OFFICE system helps manage and monitor in real time the condition of the main components of the harvester, monitor working parts, engine, transmission, progress of work and service operations, and also informs about the presence of errors, warning and emergency situations.

The powerful lighting system of working area LED VISION provides an excellent visibility when working at night.

For the operator’s convenience, the CAM VISION system is installed in the cab, providing video review of work areas, which allows you to monitor important processes without leaving the cab.

6 rollers are just the beginning!

The new POWER FLOW feeding unit is a three-stage powerful pressing of leafy stem mass for high-quality and energy-saving grinding. Uniform distribution of pressure on the feed mass makes the grinding process more precise.

The updated design of the feeding unit allowed:

- increase the reliability of the technological process;

- optimize the supply of mass to the grinding unit;

- increase the overlap area of the chopping drum relative to the feeding unit and eliminate the winding of plant stems on the axles of the rollers of the feeding apparatus and the chopping drum.

One of the most important indicators when servicing a harvester is free access to components and assemblies. The EASY FIX feeder retraction mechanism allows for unobstructed access to the chopping drum and shear plate.

The feeding unit is retracted using a hydraulic cylinder forward and to the side relative to the grinding unit, providing more convenient and faster maintenance.

To further increase productivity, the FS650 harvester is equipped with a hydraulic multi-coupling for connecting adapters, which reduces the time of their assembly, saves your effort and helps you quickly start harvesting.

The drive of lower feeding rolls is carried out by a powerful hydraulic motor through a gearbox. Thanks to this drive scheme, you get a confident and uninterrupted start of the plant mass.

To maximize the potential of the FS650 harvester, there are many solutions – the DRUM PROTECT system is one of them. Sensitive metal detector and stone detector sensors installed in the front lower roll send signals to the electronic unit of the control panel located in the cab. The system will instantly stop the drive of the feeder rollers, protecting the feeder and also saving you valuable time in case of repair. And with the help of the electrohydraulic reverse mechanism, the foreign object will be quickly removed by the reverse rotation of the rolls.

Direct mass flow – low energy consumption

A direct-flow mass wiring scheme using high-quality and wear-resistant materials allows you to obtain high throughput with minimal fuel consumption.

The MULTI DRUM universal chopping drum with 4 rows of knives is specially designed for efficient and economical cutting. Due to the special angle of the knives in relation to the shear bar, an oblique and clean cut is ensured with a reduction in cutting energy costs. The knives, due to the angle of inclination, shift the mass from the edges to the center of the drum, reducing the friction of the mass against the walls of the technological path, thereby reducing wear and increasing the efficiency of the technological process.

The drum width of 780 mm and diameter 630 mm allows you to work freely and with full efficiency at a speed of 14 km/h.

The DIRECT DRIVE chopping drum direct drive system is carried out directly from the engine crankshaft. Such a scheme guarantees the highest efficiency of the power transmission and allows to reduce the specific energy consumption.

Smooth adjustment of the cutting length is simply and conveniently made from the cab by turning the knob on the control panel in range 6-24 mm. For larger grinding, it is possible to work with 20 knives on the drum and a cutting length of 12-48 mm.

Using the AUTOSHARP system, it is possible to carry out automatic sharpening of the chopping drum knives from the harvester cab. AUTOSHARP improves forage chopping quality and harvester performance, while significantly reducing fuel consumption, and save your time and money. The number of sharpening cycles is set from the control panel in the cab.

The AUTOGAP automatic shearbar advance system is also controlled from the cab, which greatly simplifies the work and makes it easier to maintain high cutting quality.

Universal corn cracker

Gomselmash tries to take into account the client’s wishes as fully as possible. Based on your wishes, a universal corn cracker, MAX DISC CRACKER, was developed for the FS650 harvester.

The MAX DISC CRACKER with a larger diameter of 200 mm and fluted discs allows you to significantly increase the working area, which makes it possible to effectively crush corn with larger cuts. Also, due to the increased working area of the сorn cracker, its productivity is increased without loss of crushing efficiency.

As a result, you get high-quality feed mass with high digestibility rates that gives you an increase in the milk and meat productivity of your animals.

Unobstructed loading of crushed mass

The accelerator allows you to maintain a high rate of work. The three-row design of the accelerator allows the flow to be directed along the optimal path, thereby reducing energy consumption and extending the service life of materials subject to wear.

The powerful flow of the chopped mass fills the bodies of vehicles extremely tightly, ensuring maximum use of their volume and reducing the number of transportations.

The 210° swivel angle of silage spout avoids difficult maneuvering. The design of the silage spout is developed in such a way that the flow of the feed mass is directed along the optimal arc and the minimum amount of energy is consumed for its transportation. To increase the operating life of the silage spout in places of greatest load, new wear-resistant plates have been implemented in the harvester.

Increased safety of feed and its nutrients is guaranteed by the dosed preservatives application BIOMETER, which is included in the standard equipment of the FS650 harvester. Biopreservatives are added as a crushed mass from an additional tank with a volume of 300 liters using the pneumatic spray method, while the consumption of preservatives is controlled automatically.

Additional features

Often, forage crops are harvested during the rainy season, when the load-bearing properties of soils decrease. To be able to work in such conditions, the FS650 harvester is equipped with all-wheel drive as standard.

Optimal machine loading for best results. The POWER ASSIST system makes it possible to optimally load the engine depending on the feed flow. This reduces operator tiredness and improves fuel economy.

Thanks to the CTIS (Central Tire Inflation System) function, two important issues are resolved: increasing cross-country ability in the field and reducing fuel consumption during hauls. The automatic tire inflation system of the drive axle ensures optimal tire pressure depending on operating conditions, whether in the road or in the field. This system also helps reduce soil compaction and prolonging tire life.

The automatic centralized lubrication system ALS-SYSTEM, installed on the FS650 harvester, gives you the opportunity of working time effective use, reducing downtime.

The FS650 is equipped with an automatic towing device for quick and easy connection of the transport cart.

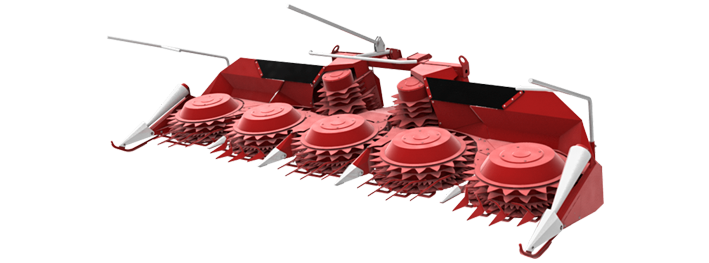

Harvesting of all types of forage crops

The adapters for the FS650 harvester create the necessary conditions for high productivity and high-quality chopping: the rotary front attachment carry the corn stalks exactly in the direction of the long axis of the feeder unit, and the pick-ups, thanks to their design, provide the shortest path of the picked-up mass to the rollers.

The rotary maize front attachment cuts the stalks cleanly and at the same height. The stalks are conveyed to the feeder unit only by the lower part. This allows you to completely avoid the loss of maize cobs, leaving a perfectly harvested field behind the machine. When harvesting wax ripeness corn with hard stalks and cobs, the quality of the cut and the uniformity of feeding of the cutting mass are still stable.

When the FS650 is used with a pick-up with feeler wheels, the contours of the field are copied accurately and without damage of the plant root system. The design of the pick-up provides the shortest path of the crop to the feeder unit, increasing the stability of the process. The pick-up device is located compactly under the auger, so when the feeder rolls are reversed, the crop is removed directly to the field. This does not require additional cleaning. In addition, you can improve your harvester's reliability with the new 2.6 m trackless pick-up.

A high-performance rotary grass header with a working width of 6 m is an effective solution for direct mowing with chopping of grass and grass mixtures. High rotor speed ensures a clean and high-quality cut.

You can get more detailed information about prices, terms of purchase and deliveries of harvesters from a dealer in your region.