Grain harvesting combine GOMSELMASH GH800 – comfortable work and excellent performance.

GOMSELMASH GH800 is a bright representative of a new generation of hybrid combines. You don't have to choose between harvesting speed and efficiency of threshing and separation, because the GH800 combine can do it all!

UNI CAB

Working in the field is easier and the combine is easier to operate thanks to the new UNI CAB premium cabin, which is equipped with everything necessary for comfortable work of the operator, and also provides excellent visibility from the workplace.

Ergonomic joystick, audio system, beverage cooler, climate control, USB port for connecting external devices, 12V socket, organizers for storing documents and small items, steering column and air suspension seat with adjustments allow you to customize your favorite seat individually and comfortably.

The ergonomic U-PAD combine control panel with logically grouped controls helps you to carry out work operations in an intuitive way without unnecessary difficulties.

The information system of HARVEST OFFICE on-board computer with a color touch screen makes the work of the combine operator as efficient and comfortable as possible. The HARVEST OFFICE system helps to manage and provide real-time monitoring of the state of the main combine functional units, control the working parts, engine, transmission, the progress of work and service operations, and also informs about the presence of warning and emergency situations.

The modern multifunctional joystick MULTI GRIP, integrated into the armrest, allows you to easily control the harvesting process. To facilitate and increase the efficiency of your work, the combine has a system that allows you to tune the working parts of the combine from the cab (threshing drum speed, concave clearance, fan speed) when changing crops.

The powerful lighting system of working area LED VISION with ten headlights contributes to comfortable and efficient harvesting even at night.

UNI CAB virtual tour

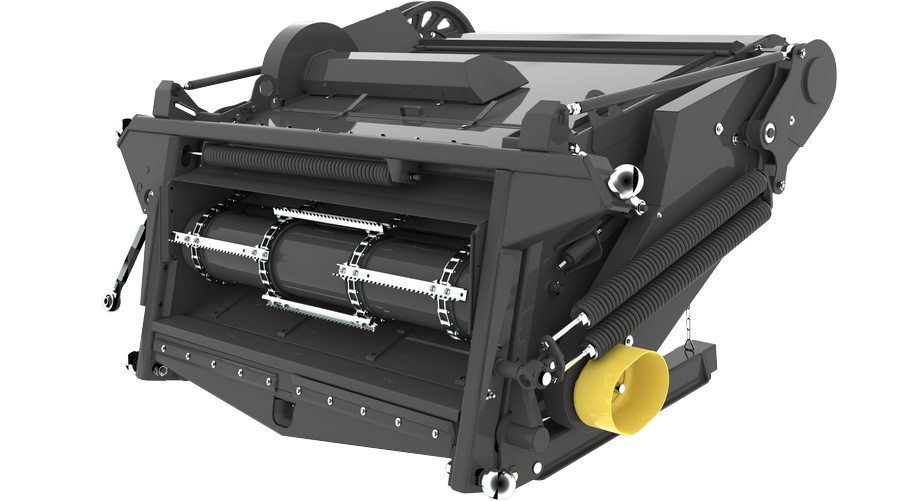

Fast and steady feeding system

The combine harvester GH800 has the high-producing feeder housing with the use of four high-quality alloy steel chains. Thanks to this, you get a steady and smooth uninterrupted start of the grain mass and the ability to work with the minimum downtime even at high speeds.

Harvesting difficult crops will not be a problem, because the hydraulic reverse function allows you to harvest in a shorter time, saving time on cleaning the feeder housing and adapter. The simple and reliable spring tension mechanism ensures a constant tension, concentrating your attention on the more important stages of grain harvesting.

The DUST CONTROL dust removal system improves visibility of the header from the cab, allowing you to load more accurate the full length of the header and avoiding small obstacles, increasing the service life of the cutterbar and reducing downtime for its replacement.

The combine harvester GH800 is designed for a variety of grain harvesting conditions, including showing excellent results at corn harvesting. This is achieved due to reinforced chains and slats of the feeder housing conveyor.

The hydraulic multi-coupling for adapters reduces aggregation time and makes this process less time-consuming.

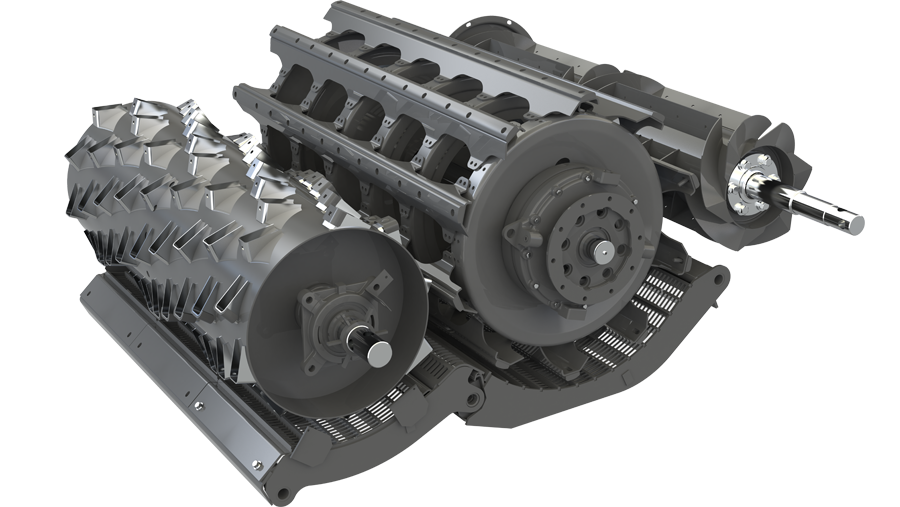

Versatile threshing and efficient separation

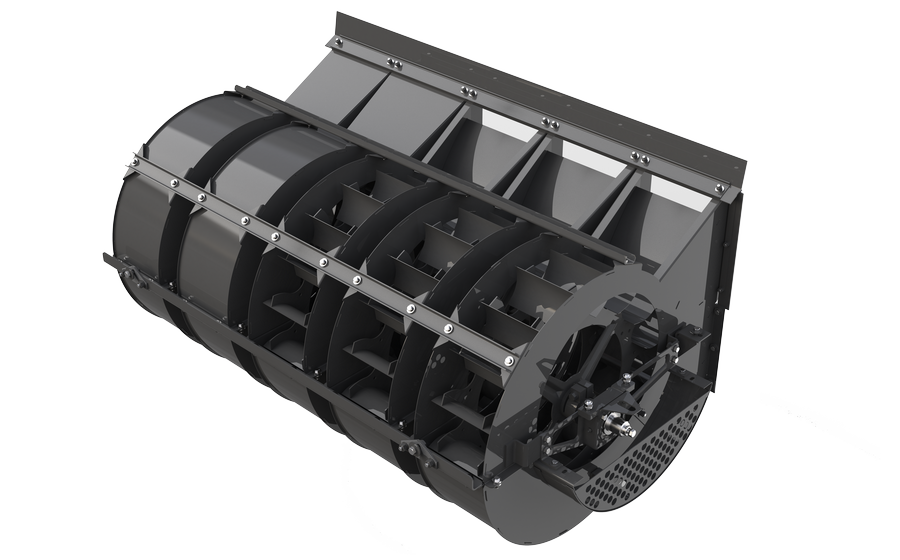

The HYBRID-FLOW threshing and separation system is everything our customers want from combine! The proven double-drum threshing scheme with a uniform acceleration of the flow of the grain mass before it enters the threshing drum, which ensures a quick and gentle threshing of your grain. The increased volumes of the drums in combination with the increased area of double concave made it possible to make the threshing path longer, and the threshing itself more careful.

Drum speeds can be easily adapted to different crops and harvesting conditions. The rotational speed is infinitely adjustable in the range from 442 to 876 rpm.

In addition, the accelerator drum evenly distribute the mass, reducing the load on the threshing drum and the main concave. That’s why you get a stable and efficient threshing, providing the combine with an advantage when harvesting wet crops.

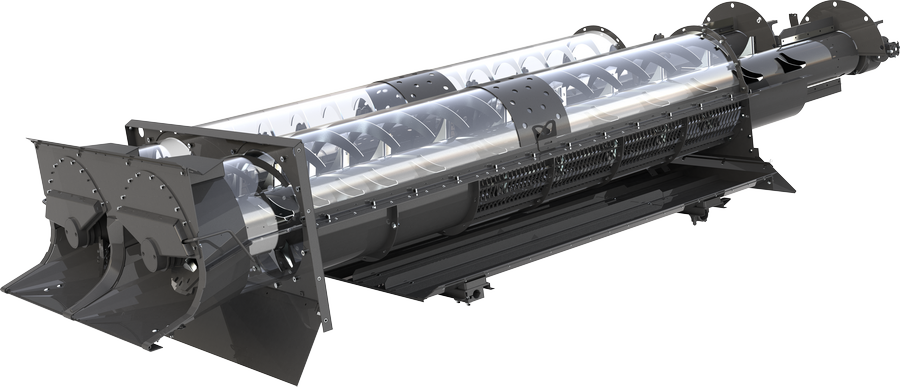

The high productivity of the GH800 combine is achieved due to two straw separator rotors with a diameter of 450 mm and a length of 4200 mm, which rotate in opposite directions, thereby creating a large centrifugal force, ensure efficient, fast and gentle allocation of residual grain so that you can get the maximum yield.

The separation system with two rotors allows the mass to be distributed more evenly, which has a positive effect on the residual threshing and cleaning.

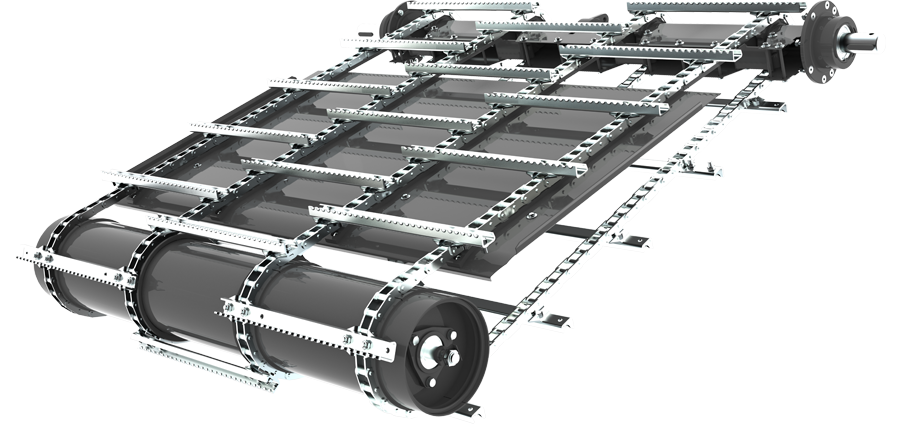

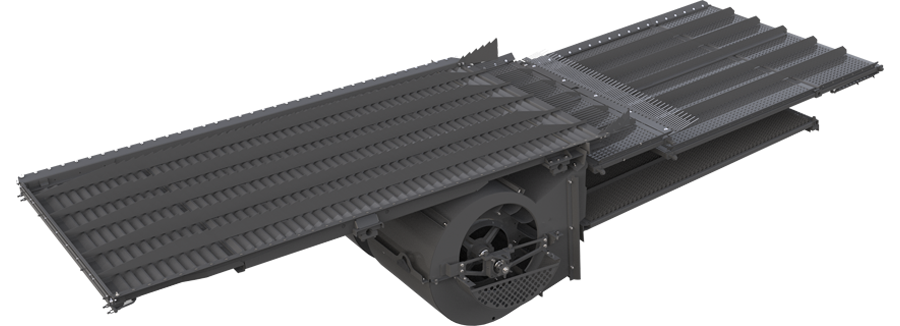

A cleaning sieves of an impressive area, three cleaning cascades, a powerful fan with a uniform distribution of air flow over the sieves – such a cleaning system satisfies the highest requirements for the purity of the obtained grain.

To be able to work on extremely harvesting conditions and hilly areas, the GH800 uses an upper cleaning sieve with an extension piece adjustable in the slope angle.

To separate a large flow of grain heap, the model GH800 provides a high-performance 5D AIR FAN cleaning system. With its help, cleaning the grain mass becomes a simple and efficient process.

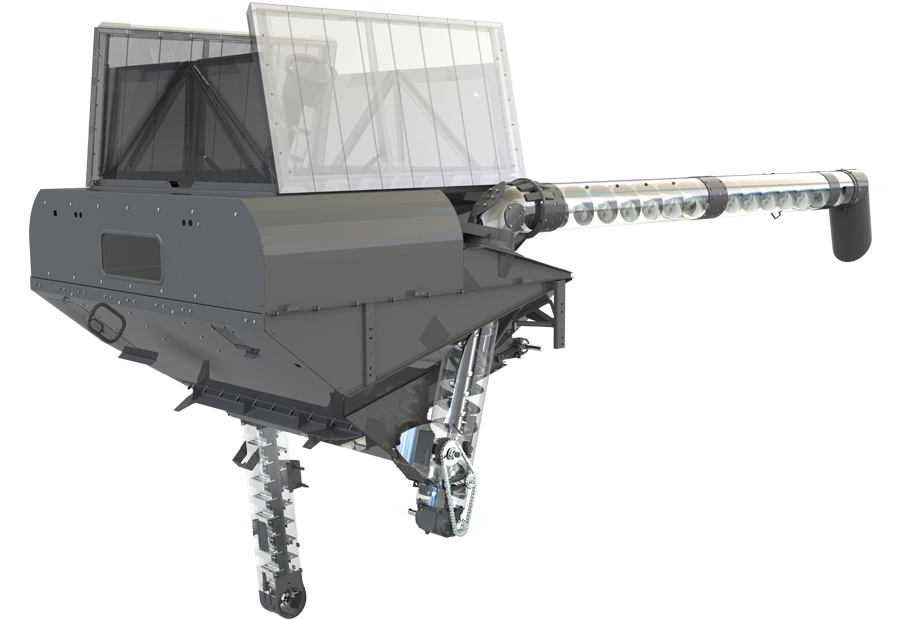

Gentle unloading in optimal time

The 9,500 liter grain tank is optimally suited for medium and large farms with field yields 50-60 centner per hectare.

Due to the optimal ratio of the unloading speed of 90 l/s and the volume of the grain tank, the emptying of a full tank occurs in less than 2 minutes without damaging the grain.

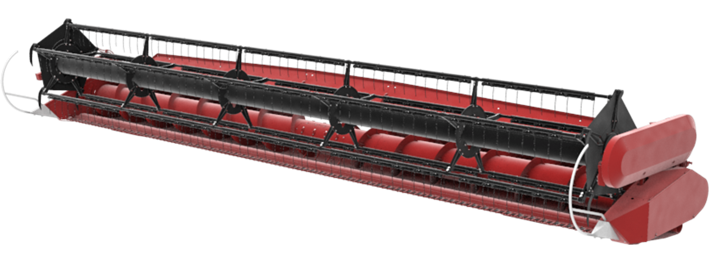

The height and length of the unloading auger make it easy to unload grain into vehicles, even on combines with 9 meters headers.

The PART-UNLOAD system, if necessary, allows you to immediately stop the unloading process, which minimizes grain losses in an unforeseen situation.

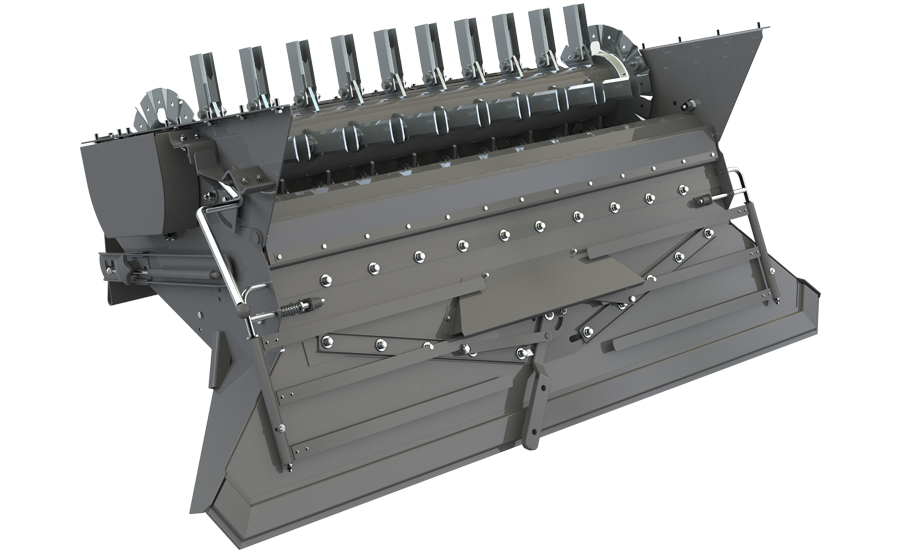

Efficient chopping and nothing extra

The time-proved OPTI-CUT 80 straw chopper with an optimal number of 80 blades ensures consistently high quality chopping and spreading of the non-grain part of the crop without the use of additional functions.

The use of a balancing disc and a floating bearing support increases the reliability of the straw chopper, reduces axial stress and thus increases the life of the bearings, saving your time and money.

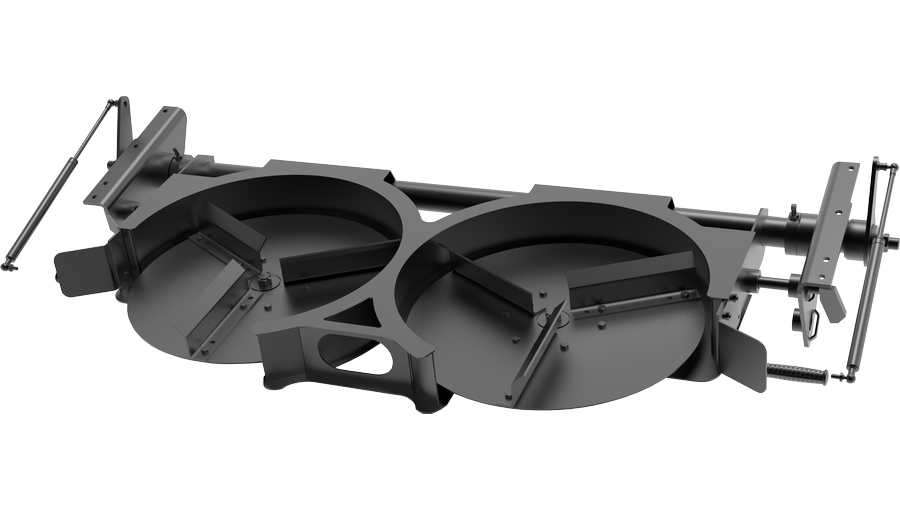

To maximize crop remains utilization, GH800 is equipped with the double disc chaff spreader called UNI-SPREADER. Adjusting the speed of the double disc chaff spreader from 400 to 800 rpm helps to successfully spread the chaff of any cereal crop without affecting the air flow of the cleaning. And the optimal location of UNI-SPREADER above the field makes it possible to dispense with additional functions under the influence of the wind.

Systems for fast and effective work

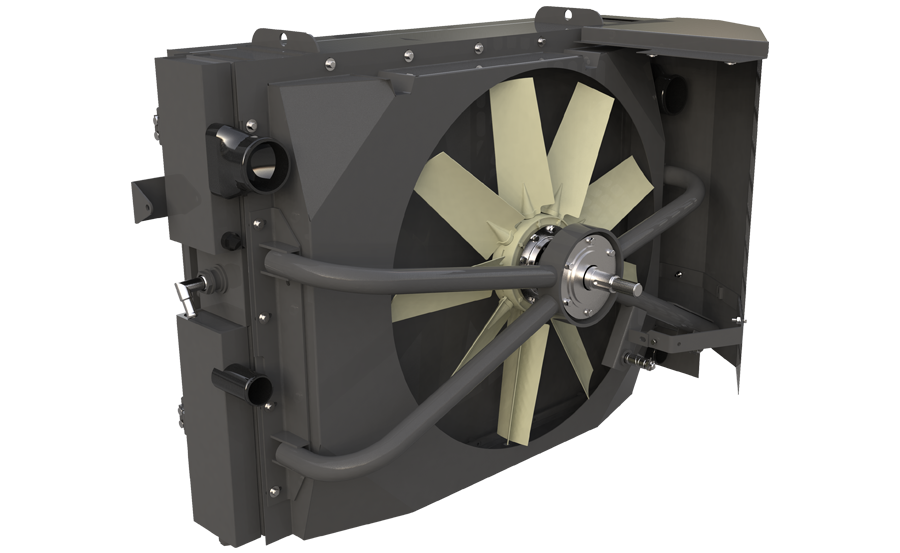

Thanks to the innovative ARC-SYSTEM the radiator is cleaned by reverse airflow generated by a reversible fan that blows out all the dirt from an air inlet zone, which increases the performance of your combine and simplifies its maintenance.

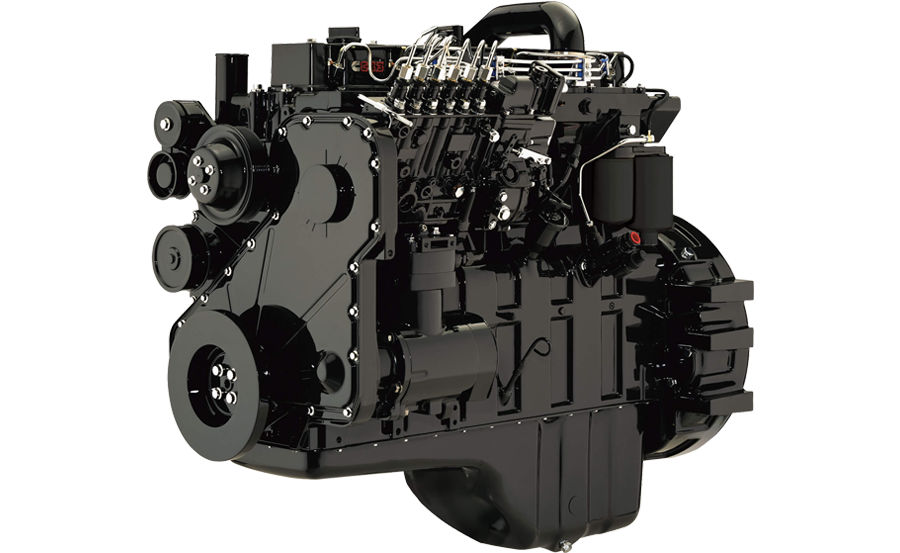

The new engine installed in the GH800 combine is an inline six-cylinder Cummins QSG-12 diesel engine with a volume of 11.8 litres, a rated power of 450 horsepower at 2000 rpm, which allows to reduce operating costs and improve fuel efficiency with increased productivity.

When you need to harvest crops that are easily damaged, such as corn and sunflower, use the reduction gear, which is included in basic configuration on the GH800 combine. This is how a gentle threshing is achieved with a minimum percentage of damaged grain.

To ensure non-stop operation during the hottest periods of harvesting, timely control and lubrication of the internal components of the combine is necessary. To minimize downtime, the combine is equipped with the automatic central lubrication system, which improves the reliability of 26 major components and reduces maintenance time.

Features of the GOMSELMASH GH810 combine harvester

Transport speed 30 km/h

Do you have a problem with long combine hauls? The GH810 combine will help you cope with this. With a transport speed of 30 km/h you will reduce haul time and thereby increase shift output.

Synchronization of reel revs with combine speed

In order to minimize operator errors, the GH810 combine is equipped with automatic adjustment of the reel rotation speed depending on the speed of the combine. This function allows you to relieve the operator and gives control of important processes to automation, which reduces losses behind the header. Also, another undeniable advantage of the GH810 combine is the hydraulic reel drive.

Electrically controlled cleaning sieve

The cleaning sieves in the GH810 combine can be adjusted without leaving the cab – this allows you to increase shift productivity.

Adjustable rotor separation area (rotor decks)

For equally efficient work on different agricultural conditions (dry / wet grain mass), the GH810 combine provides adjustment of the rotor separation area.

Mixed copying

High operating speed and throughput are integral components of the GH810 combine. Working at high speeds up to 10 km/h, in the dark, on slopes and rocky fields requires a lot of attention, but thanks to the combined copying, losses behind the header are noticeably reduced, and the combine operator can focus his attention on other important things without worrying about possible losses.

Versatility when working on different crops

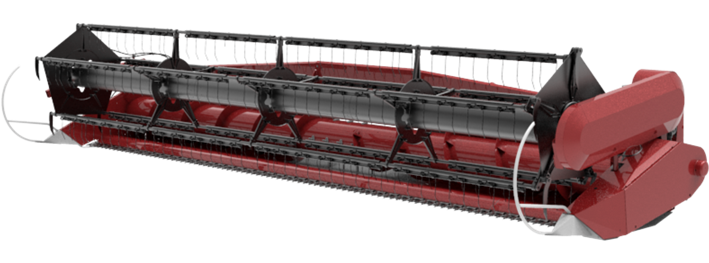

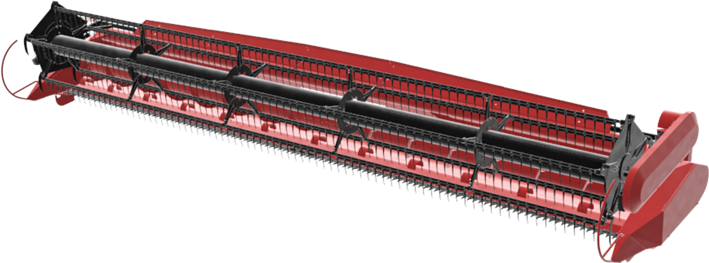

Whatever crop you grow, you can harvest it with the GH800 combine using our adapters.

You can get more detailed information about prices, terms of purchase and deliveries of combines from a dealer in your region.