SCIENTIFIC AND TECHNICAL CENTRE OF COMBINE HARVESTERS MANUFACTURING OJSC “GOMSELMASH”

branch laboratory of agricultural engineering

About the company

Founded in 1947, the specialized design bureau for the development of machines and mechanisms for animal husbandry and feed production today is the scientific and technical centre of combine harvesters manufacturing of OJSC “Gomselmash”, which is one of the largest design organizations with a powerful intellectual and material-technical base specializing in the development of complex knowledge-intensive products for the needs of agriculture, healthcare, other industries and providing engineering services.

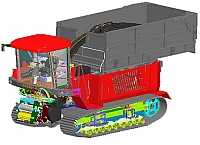

The main directions of the development of the scientific and technical centre of combine harvesters manufacturing are the creation of self-propelled grain and forage harvesters, complexes of agricultural machines based on universal power vehicles, agricultural trailed and mounted machines for harvesting feed and root crops, as well as dental complexes.

On the basis of modern computer technology, a unified computer network has been created in the scientific and technical centre of combine harvesters manufacturing, information retrieval and measurement and testing systems have been introduced, as well as computer-aided design systems, engineering calculations, technological preparation for the production of experimental samples of new equipment.

The scientific and technical centre of combine harvesters manufacturing has modern equipment for computer-aided design. Even at the development stage, the created design undergoes a series of virtual tests, during which, with the help of modern software systems, the conditions and operating modes of the design are simulated and reliability requirements are ensured.

The testing centre of the scientific and technical centre of combine harvesters manufacturing is accredited in the accreditation system of the Republic of Belarus for the right to conduct certification tests. The centre is included in the Unified Register of Certification Bodies and Testing Laboratories (Centres) of the Customs Union.

The close creative cooperation of the scientific and technical centre of combine harvesters manufacturing with academic and industry science makes it possible to optimize combines according to the criteria of fuel, material and resource intensity, economic efficiency and create a series of unified machines of a new generation.

In accordance with the Resolution of Council of Ministers of the Republic of Belarus dated 09.02.2017 No. 110, a branch laboratory of agricultural engineering was established on the basis of the scientific and technical centre of combine harvesters manufacturing in 2017, which is the largest in the Republic of Belarus. The laboratory makes it possible to carry out scientific research, development and technological work more efficiently, provide scientific support for innovative projects, pilot testing and introduction of the results of scientific and scientific-technical activities into production.

Engineering services of a branch laboratory

The Branch Laboratory of Agricultural Engineering is one of the largest design organizations in the industry with a powerful intellectual and material-technical base, which is the author of all the mass-produced equipment of OJSC “Gomselmash”. It forms a policy in developing a concept for the creation of grain harvesting, forage harvesting and other machinery for the agricultural sector not only of the Republic of Belarus, but also of foreign countries, taking into account the export potential of OJSC “Gomselmash”.

The laboratory performs a full range of research and development work on the creation of complex, knowledge-intensive, meeting all the requirements of domestic and foreign producers of agricultural products, self-propelled, trailed and mounted agricultural machines for harvesting grain crops, feed, beets, potatoes and a number of other crops.

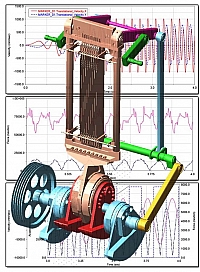

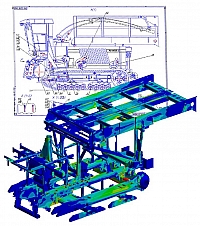

1. Comprehensive computational studies and virtual tests.

Analysis of static and dynamic strength of load-bearing structures of any topology, kinematic and dynamic analysis of operation and optimization of mechanical systems, mechanisms and transmission units, computer modeling of technological and other processes based on the study of particle motion in a continuous medium, including in an aerodynamic flow, allow to obtain the specified functional characteristics of the product and provide the required level of reliability without significant costs time and material resources. The use of modern software, techniques and technologies aimed at achieving the best result and approved on a large number of mass-produced structures is the key to our overall success.

2. Design and development of engineering documentation.

The application of modern integrated software in the field of 3D CAD by our specialists in the design process, group design and the use of engineering data management systems allows us to make the product development process fast and efficient, promptly and accurately translate design and engineering ideas into reality and enter the market with a finished product as fast as possible. Assembling a virtual product allows you to evaluate and choose the most optimal solutions before its manufacture, check the dimensional chains, collectability and appearance.

3. Development of technological documentation and production of a prototype.

The high professionalism of workers and specialists, careful control of the manufacture and assembly of the prototype ensure the exact embodiment of the designer's creative idea in metal. Our pilot production is a system of automated technological preparation of production, modern equipment with numerical control. The technologies of pilot production correspond to the technologies used in the serial production of any enterprise of the machine-building complex, which simplifies the refinement for manufacturability and accelerates the development of a new product.

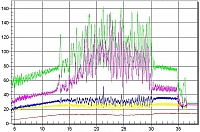

4. Comprehensive bench tests of the prototype and product refinement.

The unique bench equipment, computer control and processing bench test data results allows you to simulate operational loads and provides an accurate and objective determination of the operability of both the machine as a whole and individual element of its design, and thereby making the most optimal decisions on their refinement. Highly qualified specialists are able not only to identify a weak point in the design, but also to fine-tune the product in the shortest possible time.

5. Putting the product into production and serial support at your company.

The branch laboratory of agricultural engineering will provide the necessary assistance in organizing the production of the product, taking into account its specifics and the material-technical base that is available or will be used in the creation of the final product. In the future, serial maintenance is also possible, due to the addition of new properties and qualities to the product, depending on the wishes of the consumer.

Testing center services

Provides services for conducting certification tests of machinery and equipment for compliance with the requirements of the Technical Regulations of the Customs Union "Safety of Machines and Equipment" (CU TR 010/2011) in accordance with the scope of accreditation, as well as conducting all types of tests (preliminary, acceptance, qualification, standard, certification) of agricultural, road construction, forestry machinery and units, dental complexes, including safety indicators.

Contact information:

Head of the testing centre

Rudenkov Alexander Valeryevich

tel. +375 232 59-36-27

e-mail: ntck@gomselmash.by

Contacts

Efremova str., 61, 246035 Gomel,

Republic of Belarus

tel./fax +375 232 53-08-75

reception +375232 59-39-89, +375 232 33-30-93

e-mail: ntck@gomselmash.by

| Director of the scientific and technical centre of combine harvesters manufacturing of OJSC "Gomselmash" | Alexander Shantyko | +375 232 33-30-93 |

| General designer of the scientific and technical centre of combine harvesters manufacturing of OJSC "Gomselmash" |

|

+375 232 33-30-82 |

| Deputy director for equipment testing | Igor Mitsura | +375 232 53-33-09 |

| Deputy director for research and development | Aleksey Vyrskiy | +375 232 33-30-86 |

| Deputy director for production – head of experimental production | Igor Dubrov | +375 232 33-30-95 |

| Chief designer for grain harvesting equipment | Petr Sadov | +375 232 59-39-46 |

| Chief designer for forage harvesting equipment | Sergey Kuzmenkov | +375 232 33-30-84 |

| Chief Designer for unified systems of self-propelled vehicles |

|

+375 232 33-30-99 |

| Chief designer for small-series equipment | Aleksandr Chernoshey | +375 232 59-34-10 |

| Head of the testing centre | Alexander Rudenkov | +375 232 59-36-27 |