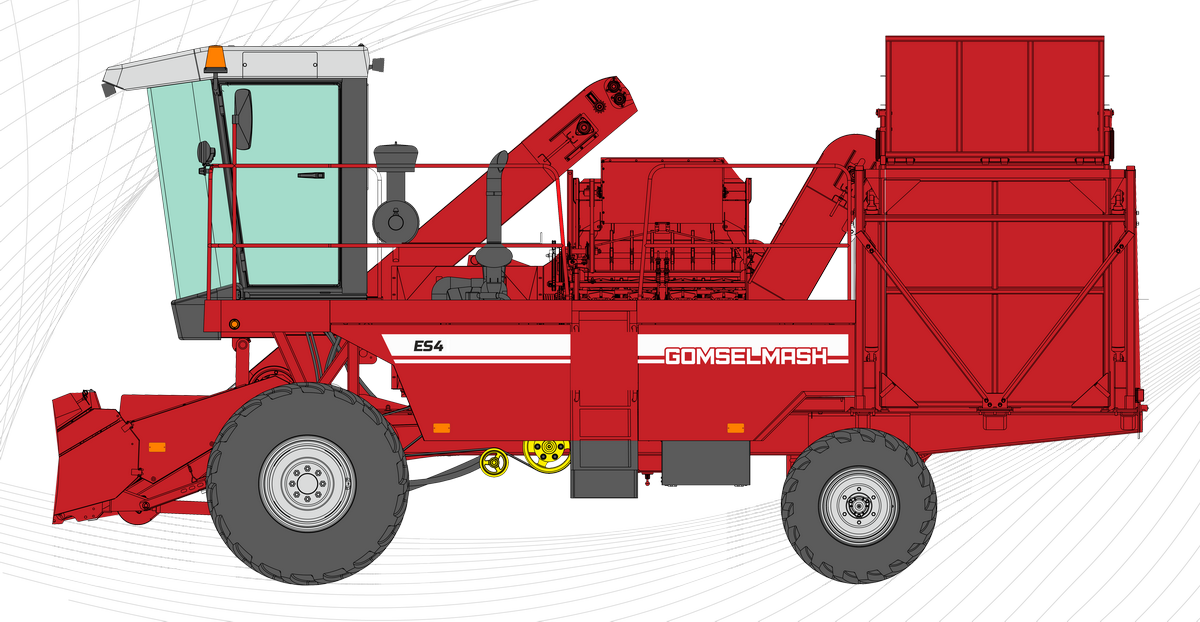

Each client has his own wishes and requirements for harvesting machines. The unique ES4 corn harvester from GOMSELMASH is produced to meet the needs of even the most demanding customers in agriculture.

The ES4 is produced for harvesting corn cobs at the stage of full grain ripeness with a moisture content no more than 25% in it. The harvester can be used on fields with a slope of no more than 8°, on all soils except mountainous areas, suburbs with soils of high moisture and low humidity, in mild climates at temperatures from -5° to +40°C.

The ES4 corn harvester performs the following technological operations:

- cutting the stems with chopping and spreading the leafy stem mass over the field;

- separating cobs from stems, cleaning cobs from wrappers, collecting cleaning cobs in a corn tank;

- separation of husked grain from a heap of wrappers and collection the grain in a corn tank;

- spreading wrappers across the field;

- unloading cobs and free grain from the corn tank into the vehicle.

The ES4 harvester is featured with a luxury, air-conditioned cab with a folding seat for an assistant operator. The optimal location of the speed control unit and the control panel directly next to the operator simplifies control of the harvester and ensures more efficient operation.

The ES4 harvester is equipped with a four-row header with a working width of 2.8 meters, designed for harvesting corn with a distance between rows from 65 to 70 cm. Five toes of the header evenly separate the crop mass and can be folded to provide access direct to the header. The cob separator carefully stores the separation of cobs from the stalks, cutting, chopping and spreading the stalks across the field, and returning the unpeeled cobs to the conveyor.

The productive front conveyor is the link between the processes of separating and cleaning the cobs. The stem catcher rollers located in the upper part of conveyor allow you to remove the stems from the heap before the unpeeled cobs enter the cob husker.

The ES4 harvester cob cleaning device effectively frees the cobs from the wrappers, separates the husked grain from the heap of wrappers and feeds the cobs onto the loading conveyor. The installed fan helps to clean the cob and remove light impurities.

The cob husker includes five groups of rollers for flawless and gentle harvest cleaning. Each group consists of two metal and two rubber rollers, the pressure of which is carried out by springs.

Under the roller cleaner there is a wrapper conveyor with two sieves for separating the husked grain. Free grain is sifted through a sieve and went into a tray for further transportation to the corn tank, thereby minimizing crop losses as much as possible.

After the cleaning process, the loading conveyor delivers cobs and husked grains into the corn tank. The drive of the chain-slat conveyor is equipped with a slipping clutch that protects the conveyor from overloads. For the operator’s convenience, there is a flap cover in the front part of the conveyor for its maintenance.

A capacious corn tank with a volume of 4.7 m3 ensures the storing of peeled cobs and their unloading into a vehicle after stopping the harvester. The design of the corn tank uses a reflector to expand the entire volume. The rotation of the corn tank for unloading is carried out by hydraulic cylinders controlled by a handle from the cabin.

The ES4 harvester is a fast, efficient method of harvesting corn cobs that provides high productivity and meets all your corn seed harvesting needs.