GOMSELMASH GR700 is a guarantee of high productivity and gentle threshing.

GR700 is the first combine harvester in the GOMSELMASH line of equipment with the ROTOR-FLOW threshing and separation system. The powerful, high-performance, universal GR700 combine embodies the world's best progressive technical solutions.

The advantage of the GOMSELMASH GR700 combine is gentle threshing, reducing the frequency of crushing and microdamage of grain. The combine is optimally suited for agricultural organizations with high grain yields and large areas sown with corn. The result of the annual efforts of agricultural producers depends on the correct choice of a combine harvester. GR700 – your right choice!

UNI CAB

The premium UNI CAB not only provides operator comfort, but also helps improve the quality and speed of work in the field, and a bonus is excellent visibility from the workplace.

The UNI CAB provides all conditions to create a comfortable and ergonomic workplace: multifunctional joystick, audio system, heated refrigerator and beverage cooler, climate control, USB port and 12V socket, organizers for storing documents and small items. The steering column and air suspension seat with adjustments allow you to customize the workplace individually for each operator, providing optimal support and comfort while working.

The intuitive design of the U-PAD combine control panel with logically grouped controls makes operation more convenient and allows you to focus on completing tasks.

The HARVEST OFFICE information system with a color touch screen ensures efficient and comfortable control of the combine. With its help you can monitor the state of the main functional units, working parts, engine, transmission, progress of service operations in real time, as well as receive information about warning and emergency situations.

With the MULTI GRIP multifunction joystick integrated into the armrest, you can easily control the harvesting process. Also, to facilitate and increase the efficiency of your work, the combine is equipped with the AUTOSYNC reel speed synchronization system, the CROP PRESET system for pre-setting the working parts for the selected crop and the LOSS CONTROL system for electric sieve adjustment mechanisms. These electronic assistants greatly simplify operator tasks and increase work efficiency.

The LED VISION lighting system with ten powerful LED headlights provides bright and uniform illumination of the work area, allowing the operator to clearly see all the details of the harvesting process. This system allows the combine operator to continue harvesting even after sunset, increasing productivity.

The CAM VISION system gives the operator full control over the processes of grain tank filling, grain unloading and maneuvering. Thanks to video cameras located at important points of the machine, the operator can monitor these processes on a special monitor directly from the cab.

Powerful start with minimal energy consumption

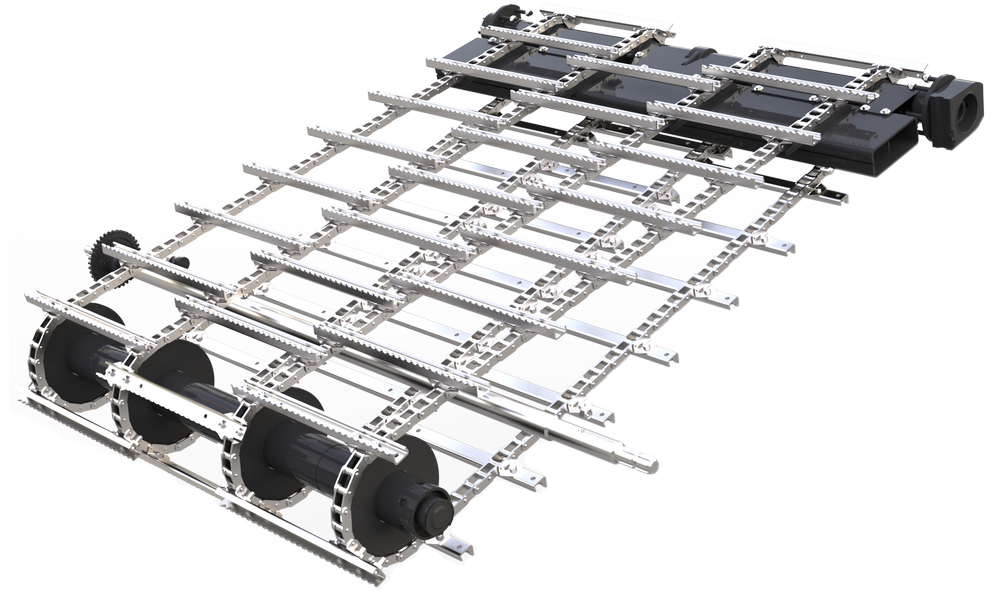

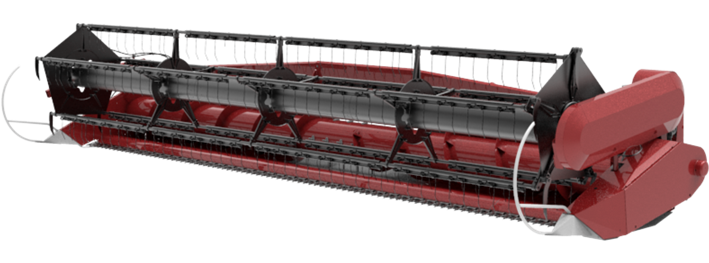

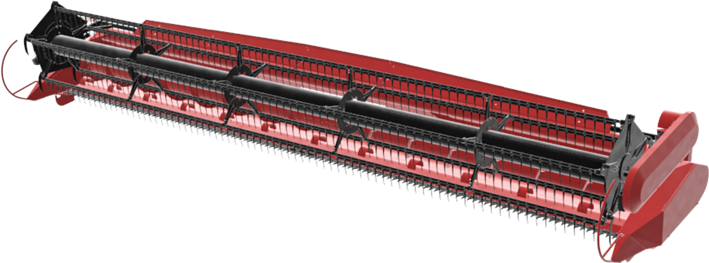

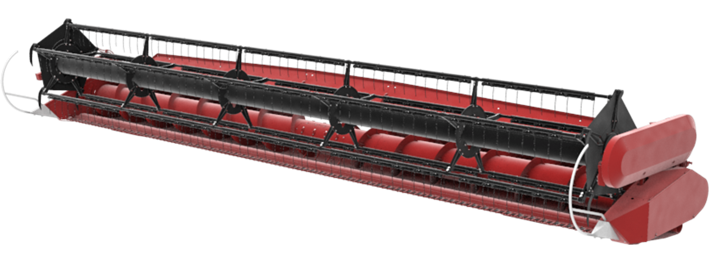

The GR700 combine, thanks to improved feeder housing, provides optimal crop feeding, which contributes to efficient threshing with reduced energy consumption. In addition, the GR700 is equipped with a 7.5 meter width header with the ability to extend the table and a hydraulic reel drive, which allows it to adapt to different types of crops and working conditions. The combine can be equipped with various headers and adapters for working with grain and soybean crops, as well as corn and rapeseed, which makes it a universal solution for a variety of agricultural tasks. The adapter hanging system with a hydraulic multi-coupling greatly simplifies the aggregation process, saving operator’s time and efforts.

Throughput and high working speed are integral components of the high productivity of your combine, and therefore your work. Working at high speeds up to 10 km/h, at night, on slopes and rocky fields requires a lot of attention, but thanks to the SELF-CONTOUR electro-hydraulic relief copying system, losses behind the header are noticeably reduced and the operator can focus its attention on other important things, without worrying about possible losses. SELF-CONTOUR provides in a fully automatic mode the maintaining of cutting height, soil pressure and position of the header relative to the ground in both longitudinal and transverse directions. These advantages of the GR700 allow you to efficiently load your combine and get the maximum economic benefit from its use.

Effective protection against stones, a reliable and easy-to-maintain mechanical stone trap prevents damage to the combine mechanisms, which is an important factor in maintaining continuity of operation.

The GR700 combine, thanks to its high throughput and operating speed, represents an important link in the agricultural production chain. It ensures efficient harvesting, minimizing losses and increasing overall productivity. The SELF-COUNTOUR system, which automatically follows the field relief, plays a key role in achieving this goal, allowing the combine operator to concentrate on other operations without worrying about crop losses. This is especially important when working at high speeds where precision and attention to detail are required.

The use of high-quality materials in the production of feeder housing conveyors guarantees their reliability and reduces the need for frequent repairs, which is an important factor for agricultural organizations seeking maximum profit.

Reverse of the feeder housing conveyor is an integral function in combine harvesters, which allows you to adapt to different harvesting conditions. The use of a hydraulic motor in such systems provides smooth control of the conveyor speed, which contributes to more efficient cleaning of the equipment. This in turn reduces machine downtime and increases overall productivity.

The DUST CONTROL dust removal system used in the GR700 combine harvesters is an advanced solution for increasing harvesting efficiency. It not only keeps the air in the operator's cab cleaner, but also helps the header operate more accurately, allowing the operator to make more use of the header's width.

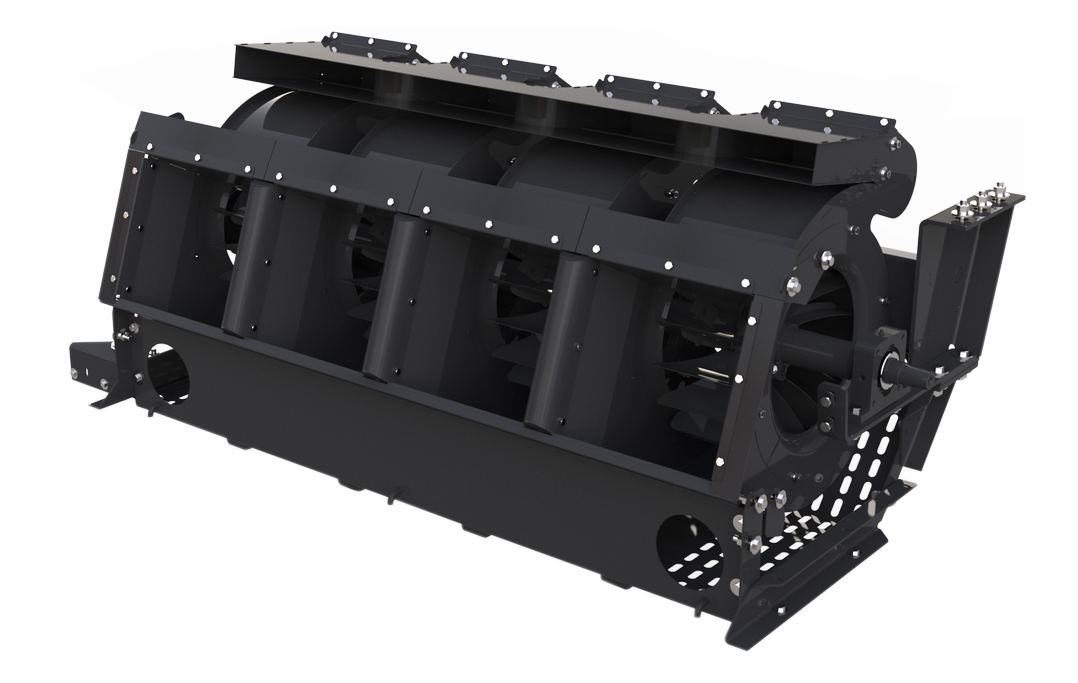

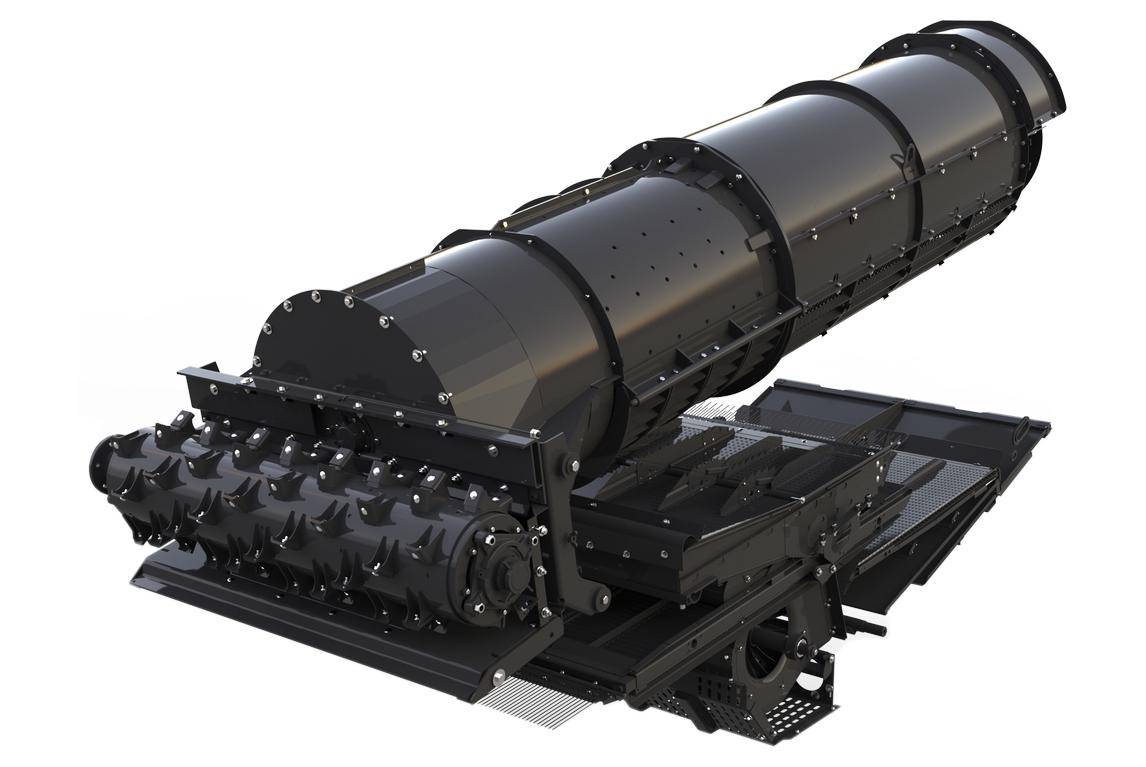

ROTOR-FLOW – effective separation at various crops

The threshing and separating device of the GR700 combine is an innovative solution in agricultural technology that ensures high harvesting efficiency. Thanks to the unique rotor design with a diameter of 770 mm and the ability to adjust speed of rotation from 250 to 1 150 rpm, the optimal combination of productivity and quality of grain processing is achieved. This allows you to adapt to different harvesting conditions and types of crops, while minimizing losses and damages of grain. The simplicity of the GR700 design, the absence of unnecessary augers and drive mechanisms, makes its maintenance more convenient and reduces power consumption. Thus, the GR700 is an example of modern agricultural machinery that combines advanced technology and ease of use.

The ROTOR-FLOW threshing and separation system allows threshing with a lower linear speed in comparison with classic combines, which reduces crushing and microdamage of grain and also improves its sowing qualities.

The effectiveness of the ROTOR-FLOW system is confirmed by its ability to release the majority of grain through the process of wiping from the wheat head and the action of centrifugal forces, while minimizing the shock impact typical of classical threshing devices. This approach makes it possible to achieve minimal yield losses even at high harvesting speeds, which makes the ROTOR-FLOW system the preferred choice for modern agricultural organizations seeking to increase the productivity of equipment and the quality of grain crops.

The ROTOR-FLOW system is equipped with one of the largest rotors on the market with a diameter of 770 and a length of 4 200 mm, which provides high performance while gently threshing of your grain. The large rotor of the GR700 combine does not require high speed of rotation for effective threshing and separation, which reduces energy costs and increases the life of key components!

The threshing process is simple and effective! The grain mass comes from the feeder housing to an accelerator drum with a diameter of 450 mm, which has two speed ranges.

In the area of the accelerator, the flow of grain mass is drawn and optimized for equable feeding into the rotor, which contributes to high and stable performance, absence of peak loads on the rotor and lower power consumption!

Then the mass flows onto spiral blades of a special tapered shape, which allows for a stable and equable feeding. Eight highly efficient bars ensure gentle and high-quality threshing. 64 shear fingers with wear-resistant slats are responsible for the uninterrupted movement of the grain mass along the rotor, which carry out this process in a spiral along the rotor between the fixed decks and the casing. The casing, offset from the center of the rotor, creates the effect of compression and fluffing, thus the separation of grain is also carried out due to the mass’s own friction, making this process more gentle!

The GR700 combine is equipped with a high-tech cleaning system, which includes cleaning sieves with a large area of 5.0 m2 and many-stage cleaning cascades. This ensures effective separation of grain from impurities, guaranteeing its high purity. The powerful fan distributes the air flow evenly across the sieves, which is key to achieving optimal cleaning results. Such systems certainly meet the strictest requirements for harvesting quality.

Due to the high productivity of the combine, the difficulty of cleaning the grain mass also increases. Thanks to the high-capacity cleaning system with four sections, cleaning a large flow of grain mass becomes a simple and effective process.

The simple but effective design of the GR700, without the additional augers, drives, gears and unloading beaters found on other machines with classic threshing and separation system, not only simplifies maintenance and reduces power consumption, but also reduces grain damage. High quality grain is your success!

Brilliantly conceived unloading

Unloading the grain tank is a very important step in the harvesting process. The efficiency of this process can significantly impact the overall productivity and economics of agricultural production. And the modern technologies of the GR700 combine help optimize this process.

The optimal balance between the characteristics of the GR700 grain tank with a volume of 10 000 liters and an unloading speed of at least 110 l/s allows you to unload it in the shortest possible time. It helps save your time and avoid grain damage.

In order to save your money, the GR700 combine is equipped with the PART-UNLOAD and OPTI-UNLOAD systems. The PART-UNLOAD system, if necessary, allows to stop immediately the unloading process and empty the unloading auger, minimizing grain losses. The OPTI-UNLOAD system makes it possible to unload grain with the powered down drive of the thresher. During the harvesting season, this function saves a large amount of your fuel.

Optimum chopping is easy

The process of chopping and spreading straw across the field is an important part of agricultural work, as it contributes to more efficient use of straw as fertilizer. High-quality chopping and uniform distribution of straw helps to improve the structure of the soil, enrich it with organic matters and maintain moisture.

Chopping straw speeds up its decomposition and facilitates uniform distribution across the field, which is important for maintaining soil fertility and improving yields.

To process crop residues, the GR700 combine is provided with an OPTI-CUT 80 straw chopper. 80 knives are installed on the straw chopper, which carry out high-quality and fine chopping, and then spread the non-grain part of the crop. The obtained material easily decomposes and gives nutritional properties to the soil, thereby increasing the yield of your fields in the following seasons.

Everything for comfortable and effective work

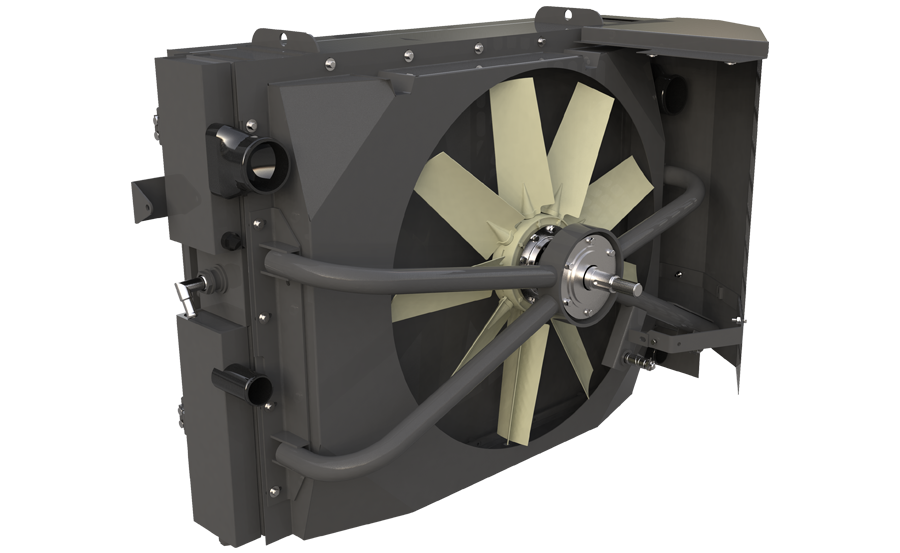

Also, in order to save your precious time, the GR700 combine has an innovative active radiator cleaning system called ARC-SYSTEM. The radiator is cleaned by reverse airflow generated by a reversible fan that blows out all the dirt from an air inlet zone, which increases the performance of your combine and simplifies its maintenance.

The automatic centralized lubrication system installed on the GR700 combine allows you to make efficient use of your working time, reducing downtime and maintenance time.

Overall, the GR700 is a well-designed and technologically advanced combine harvester that provide high productivity and cost efficiency, making it a valuable asset for any agricultural organization. Its ability to adapt to different conditions and harvesting requirements makes it a go-to tool in achieving agricultural goals.

Versatility when working on different crops

Whatever crop you grow, you can harvest it with the GR700 combine using our adapters.

You can get more detailed information about prices, terms of purchase and deliveries of combines from a dealer in your region.