Grain harvesting combine GOMSELMASH GS12A1 is a combination of comfort, time-tested technologies and technical solutions.

Productivity, versatility, gentle threshing, harvesting of high-straw and wet grain, simplicity are the undeniable advantages of the GS12A1 combine, which make it the most demanded in its class. Choosing this combine model, you can be sure that you will get a time-tested reliable harvester.

LUX CAB

A comfortable workplace is a must have for every operator. That is why “Gomselmash” analyzed the wishes of farmers from across the world and developed a comfortable cabin of a new generation LUX CAB, in which special attention is paid to the workplace ergonomics and the interior.

The air suspension seat improves productivity and reduces operator fatigue. Multiple seat adjustments, a new steering column and steering wheel allow you to set up a comfortable working position and achieve maximum performance throughout the shift.

The ergonomic U-PAD combine control panel, modern MULTI GRIP joystick and on-board computer HARVEST OFFICE with a color touch screen assist in choosing the most optimal combine settings depending on the current conditions, while ensuring simplicity and convenience in operation. The HARVEST OFFICE system gives you the opportunity to simultaneously control the combine and provide real-time monitoring of the state of its main functional units, control the working parts, engine, transmission, the progress of work and service operations, and also informs you about the presence of warning and emergency situations.

Also, to facilitate and increase the efficiency of your work, the combine has a system that allows you to adjust the working parts of the combine from the cab (threshing drum speed, concave clearance, fan speed) when changing crops.

The powerful lighting system of working area LED VISION provides an excellent visibility when working at night. Also, the location of the side mirrors in LUX CAB has become more convenient.

Original constructional decisions and arrangement of the combine working systems provide maximum results by reasonable power consumption, which guarantees the optimal cost of which guarantees the optimal cost of harvested grain.

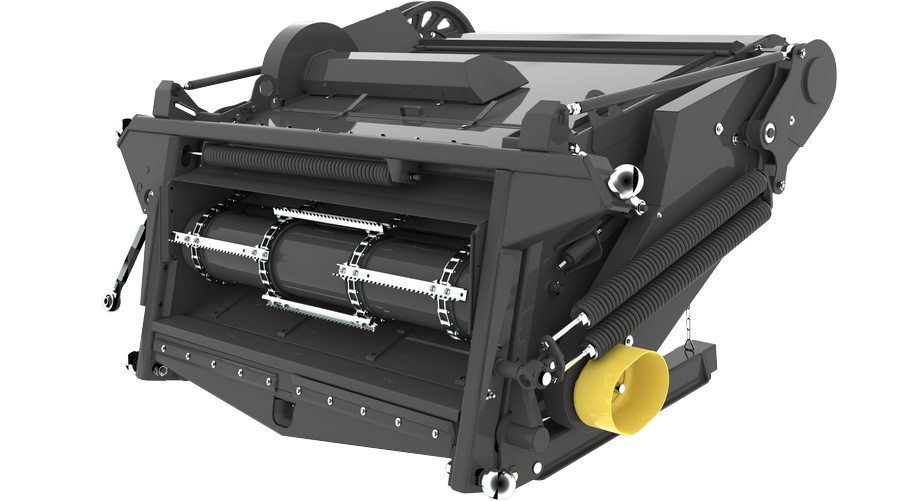

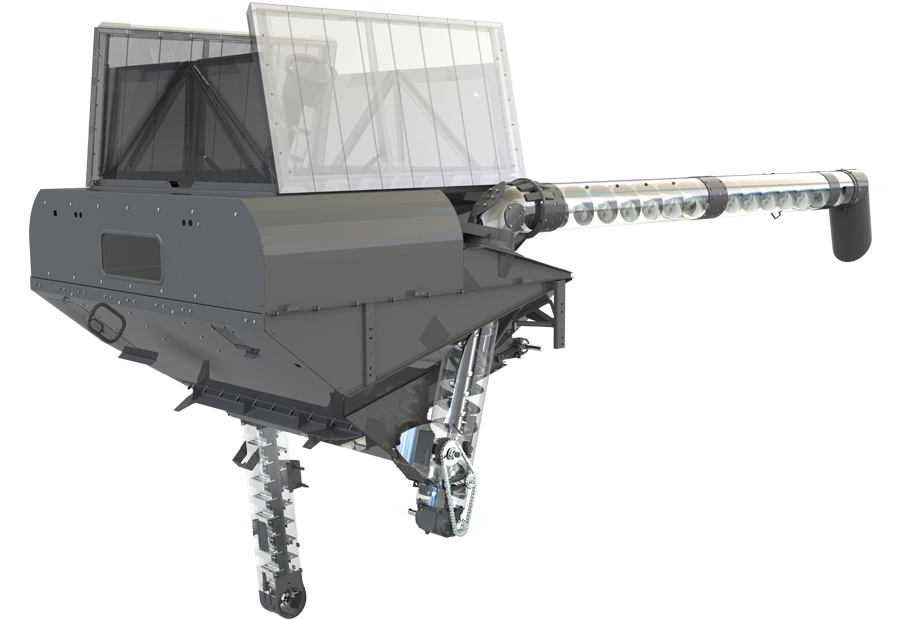

Feed system for all harvesting conditions

You get a reliable and steady start of the grain mass and the ability to work with the minimum downtime during the most difficult period of harvesting. It's possible thanks to the chain-and-slat conveyor installed in the feeder housing using high-quality alloy steel chains.

The extended lower shaft lever makes it possible to forget about the control of the voltage of the chains under various harvesting conditions.

Harvesting difficult crops is made easier as the hydraulic reverse feature allows you to harvest in a shorter time, saving you time cleaning the feeder housing and adapter.

The DUST CONTROL dust removal system improves visibility of the header from the cab, allowing you to load more accurate the full length of the header and avoiding small obstacles, increasing the service life of the cutterbar and reducing downtime for its replacement.

The simple and reliable spring tension mechanism provides constant tension, concentrating your attention on more important harvesting steps.

The hydraulic multi-coupling for adapters reduces aggregation time and makes this process less time-consuming.

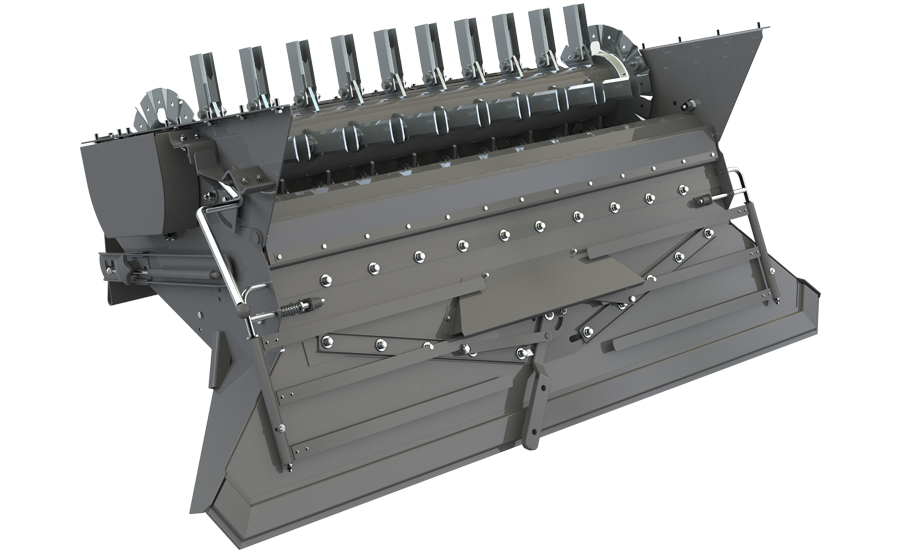

Gentle threshing and clean separation

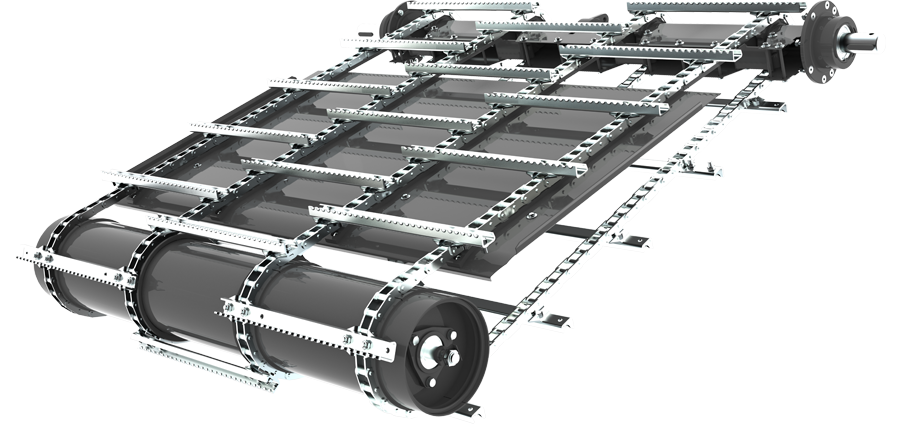

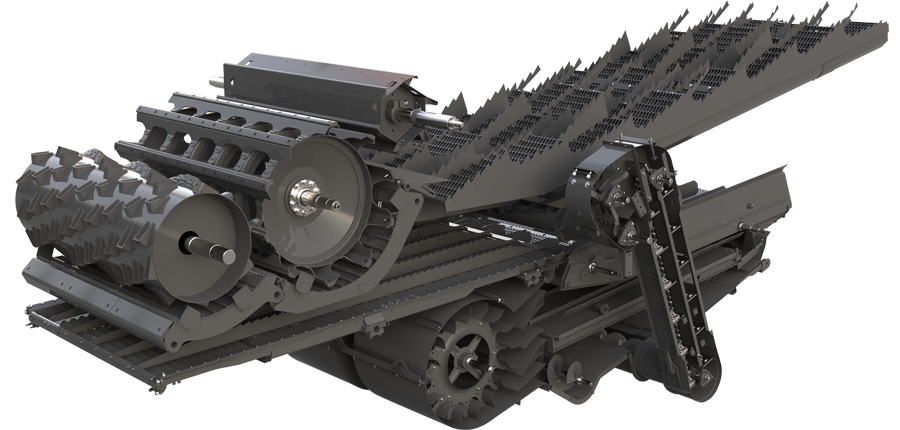

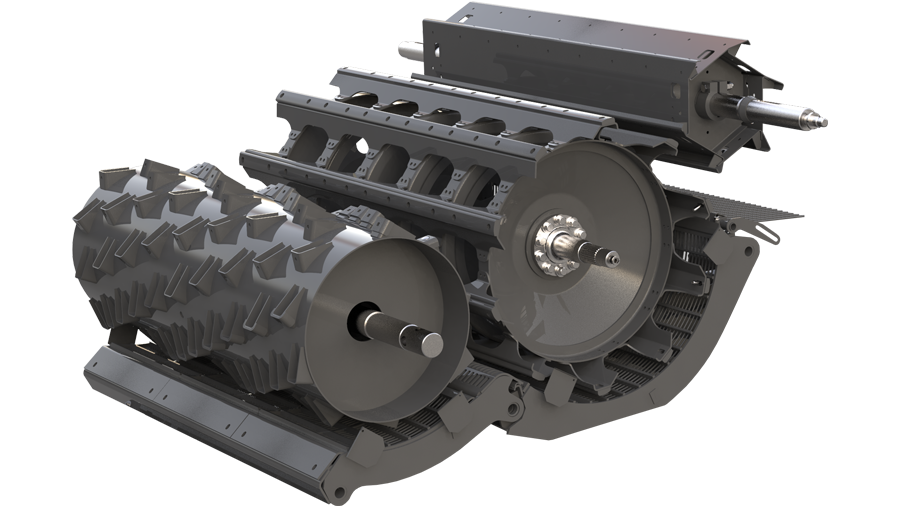

The base of the GS12A1 combine is the classic TWIN DRUM-FLOW threshing and separation system, which has repeatedly proven its efficiency on any agricultural background and harvested crops.

The productivity of the GS12A1 combine is achieved by accelerating the flow of grain mass by an accelerator drum in front of the threshing drum. The increased volume of the drums, in combination with the increased area of the double concave, allowed to make the threshing path longer, and the threshing more gentle.

Moreover, the accelerator drum evenly spread the mass, reducing the load on the threshing drum and the main concave. That's why you get stable and efficient threshing, providing the combine an advantage when harvesting wet crops.

The GS12A1 combine is designed for harvesting in the most extremely harvesting conditions, when there is a possibility of concave clogging. To solve this problem, the GS12A1 combine is equipped with the DRUM RESET system, with which you can quickly and effectively eliminate the formed clogging without stopping the threshing drum. The DRUM RESET function is activated by the pedal right under the seat. This operation takes only few seconds.

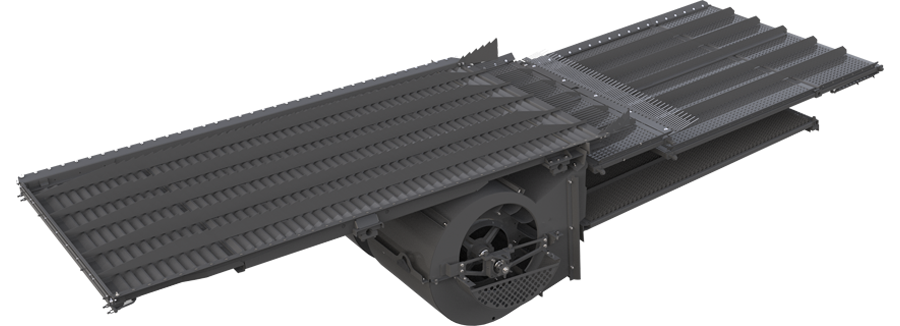

A cleaning sieves of an impressive area, three cleaning cascades, a powerful fan with a uniform distribution of air flow over the sieves – such a cleaning system satisfies the highest requirements for the purity of the obtained grain.

The presence of seven cascades with an optimal height difference on each of the five straw walker keys and a large amplitude of the keys movement improve the separation of grain from the straw heap, maintain stable performance and reduce losses.

Optimal unloading

9,500 litres grain tank equipped with a vibro bottom, is optimally suited for medium-sized farms with field yields 30-45 centner per hectare.

A full grain tank is emptied in less than 2 minutes thanks to an unloading speed of 90 l/s. There is no need to wait for optimal grain moisture! With the help of the STICK CONTROL system, you can harvest high-moisture grain, thereby reducing the downtime of your machines.

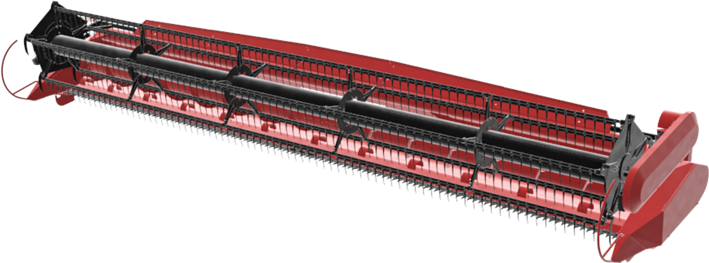

The height and length of the unloading auger make it easy to unload grain into vehicles, even on combines with 9 meters headers.

Required chopping result without complications

The time-proved OPTI-CUT 80 straw chopper with an optimal number of 80 blades ensures consistently high quality chopping and spreading of the non-grain part of the crop without the use of additional functions.

The use of a balancing disc and a floating bearing support increases the reliability of the straw chopper, reduces axial stress and thus increases the life of the bearings, saving your time and money.

Extended PROFI configuration

The GS12A1 combine is also available in the extended PROFI configuration, which includes:

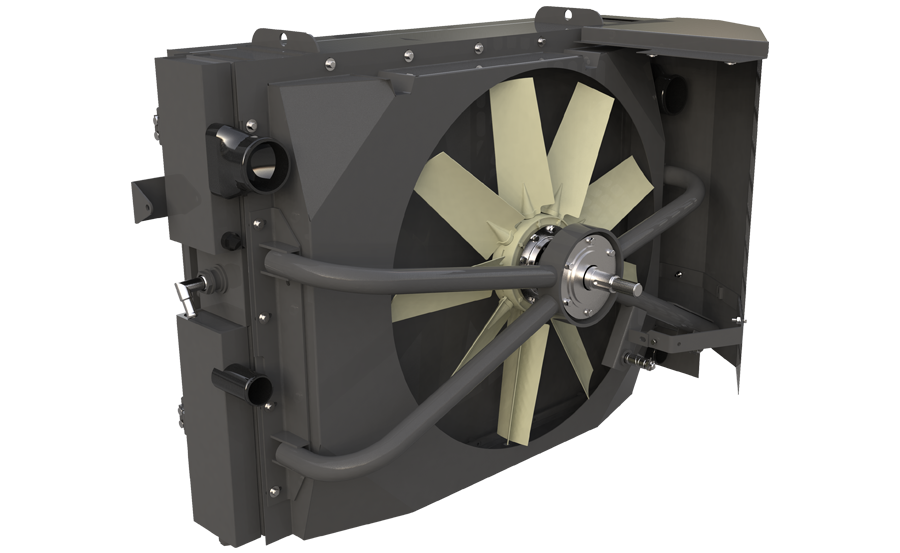

- the ARC radiator cleaning system

- threshing drum reduction gear

- automatic centralized lubrication system

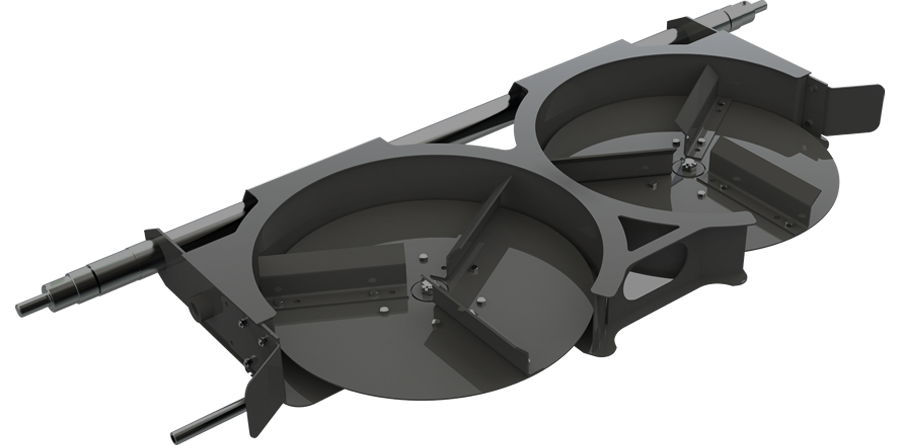

- the UNI-SPREADER chaff spreader.

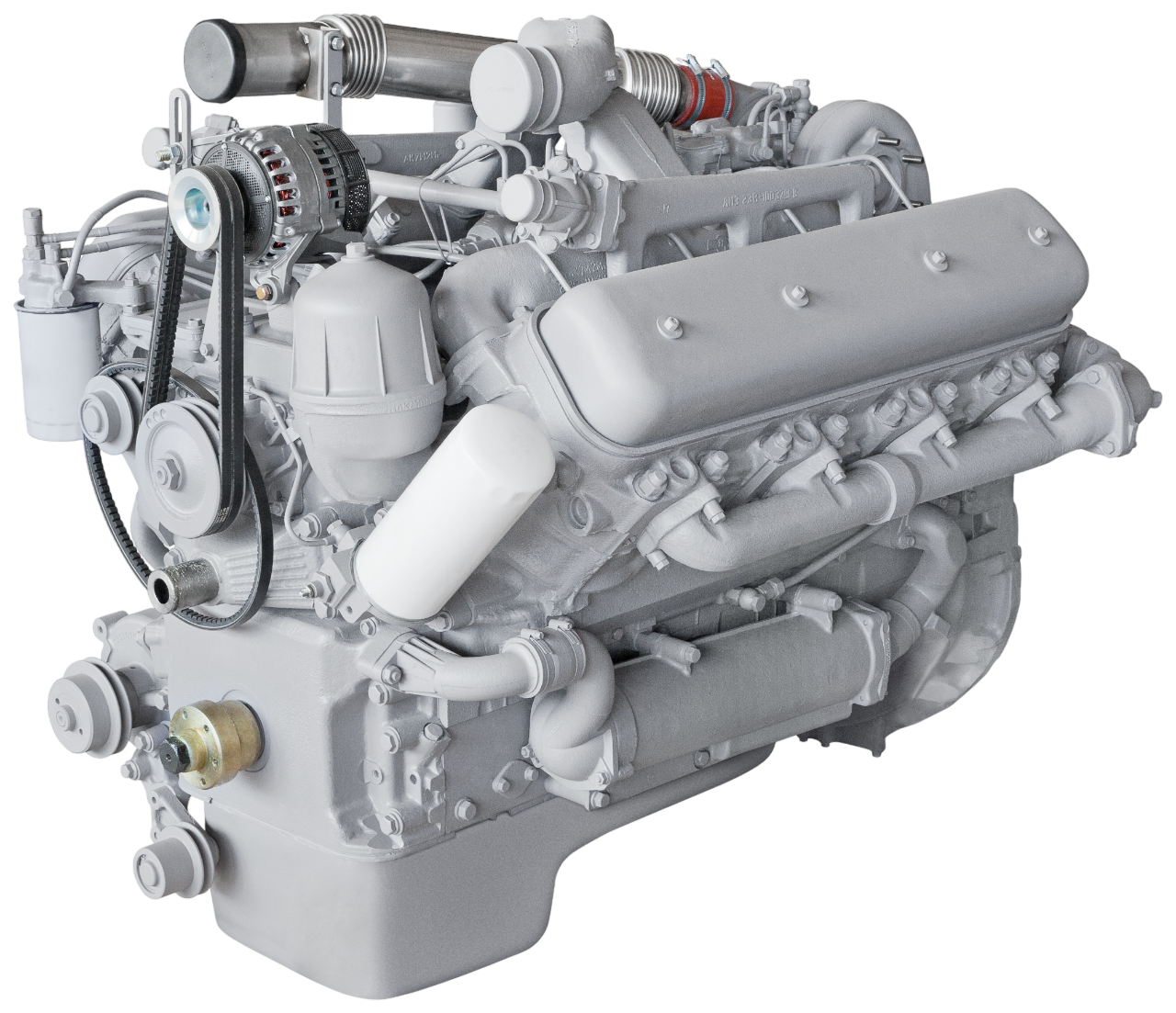

The time-tested engine installed in the GS12A1 PROFI combine is a V-shaped eight-cylinder diesel engine YaMZ-238 with a rated power of 330 h.p. at 2000 rpm, which allows to reduce operating costs and improve fuel efficiency with increased productivity.

Thanks to the innovative ARC-SYSTEM the radiator is cleaned by reverse airflow generated by a reversible fan that blows out all the dirt from an air inlet zone, which increases the performance of your combine and simplifies its maintenance.

The GS12A1 PROFI combine is designed for harvesting the maximum amount of grain and cereal crops. To do this, when harvesting crops that are easily damaged, such as corn, sunflower and others, a reduction gear is included in basic configuration. In this way, gentle threshing is achieved with a minimum percentage of damaged grain.

To ensure non-stop operation during the hottest periods of harvesting, timely control and lubrication of the internal components of the combine is necessary. To minimize downtime, GS12A1 PROFI is equipped with the automatic central lubrication system, which improves the reliability of 26 major components and reduces maintenance time.

UNI-SPREADER mounted on GS12A1 PROFI ensures equable chaff spreading to the optimum width in all harvesting conditions. The reliable and simple components of UNI-SPREADER allow you to work effectively even under extremely harvesting conditions, without affecting the air flow of the cleaning.

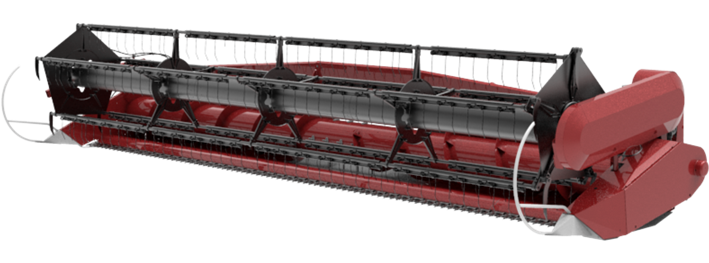

Versatility when working on different crops

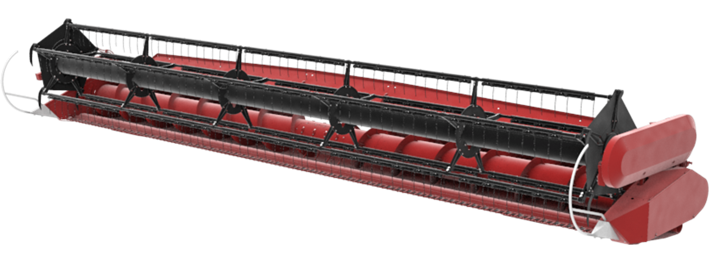

Whatever crop you grow, you can harvest it with the GS12A1 and GS12A1 PROFI combines using our adapters.

The GS12A1 and GS12A1 PROFI all-wheel drive combines is suitable for working in difficult conditions: with steady rains, poor flotation and low soil bearing capacity.

You can get more detailed information about prices, terms of purchase and deliveries of combines from a dealer in your region.